along its outer cmh (e). Steam may be produced by pouring water ovei the

the flue (6) ; and also, if desirable, under the bed of earth, hy mtl'oducmg water throu h

a pipe ivith a funnel (A) ; .aU the fines being iui-nished with a COTrse of bricks Mong the

outer edges of the cover, so as to form a trough between them. The m u teo om ( «

is a vault between the two p its ; and, hy means of small o pem np (i), to be closed at

ple.asure by bricks, may receive heat from either or both of t e tbMltVh

most severe ivcatlicr, the warmth incident to its situation wiU be siifficient foi the

o f muslirooms. I t may be fitted up with shelves (A) m t e usual way ; and may also

be used for forcing succory, rhubai’b, sea kale, winter potatoes, &c.

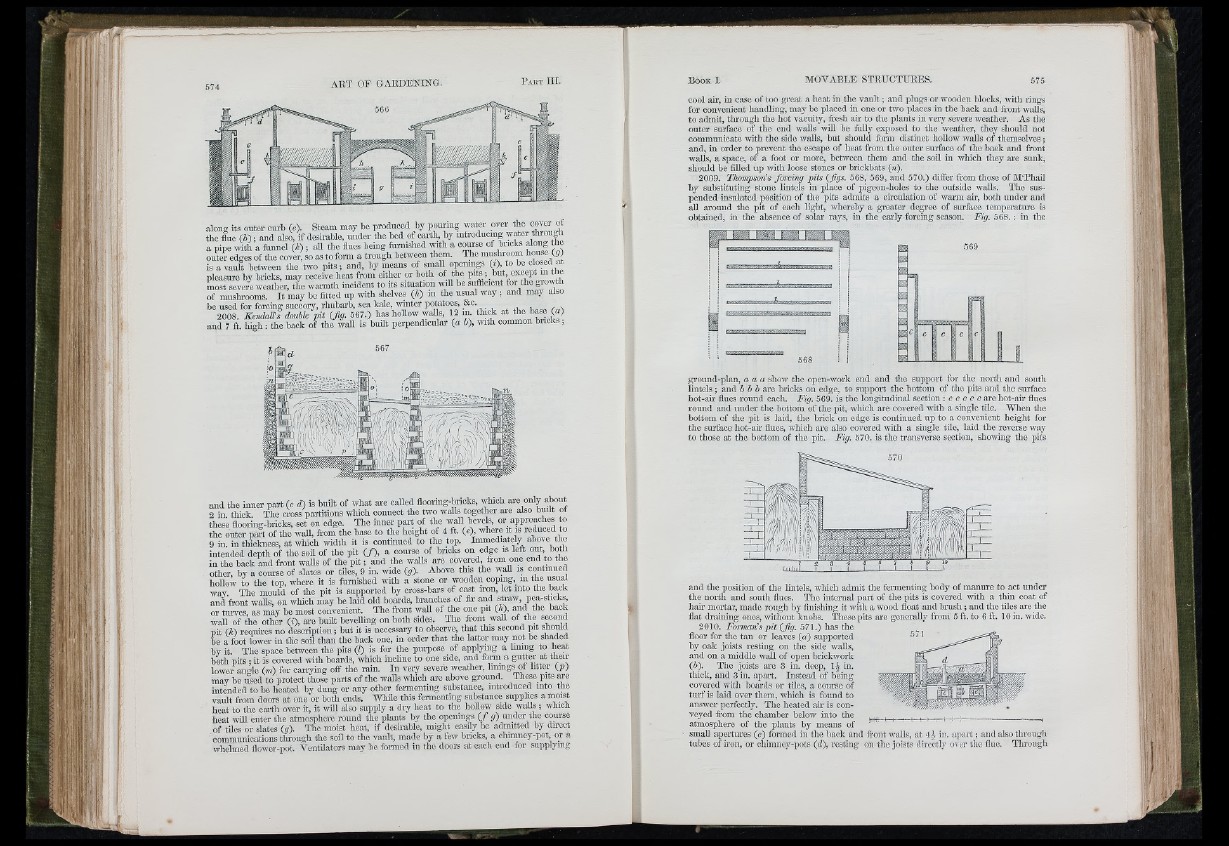

2008. KemlaU’s double p it (fig. 667.) has hollow walls, 12 m thick at t e base (a)

and 7 ft. h ig h ; t e hack of the wall is huilt perpendicular (o 6), with common b u c k s ,

and t e inner part (c d) is hnilt of what are called flooring-hricks, which ai'e only about

2 in thick. The cross pai-titions which connect the two walls together are also built ot

these flooring-biicks, .set on edge. Tlie inner part of the l ÿ l beve s, or approaches o

t e outer part of the wall, from the base to t e height of 4 ft. (e), where it is reduced to

9 iu. in thiekness, at which width it is continued to the top. Immediately above the

intended depth of t e soil of the pit ( f ) , a course of bricks on edge is left out both

in t e back and front walls of t e pit ; and t e walls are covered from one end to the

other, hy a course of slates or tiles, 9 in. wide (g). Above this t e wall is continued

hollow to t e top, where it is furnished with a stone or wooden coping, m the usual

way. The mould of t e pit is supported by cross-bars of cast u-on, let into the back

and front walls, on which may he laid old boards, branches of fir and straw, pea-sticky

or turves, as may ho most convenient. The ft'ont wall of t e one pit (Ay and " 7

wan of t e other (i), are built bevelling on both sides. Tlie front waU of th® second

nit (A) requfres no description ; hut it is necessaiy to observe, that this second pit should

be a foot lower in the soü than t e hack one, in order that t e latter may not he shaded

by it. The space between the pits (1) is for the piupose of appljmig a hning to heat

both pits ; it is covered with hoards, which incline to one side, and form a gutter at their

lower angle (m) for cimying oif the rain. In veiy severe weather, luungs of litter (p)

may be used to protect those pai-ts of t e waUs which are above ground. These pits are

intended to he heated hy dung or any other fermenting substance, introduced mto the

vault from doors at one or hoth ends. Whüe this fementing substance supplies a moist

heat to t e eaith over it, it will also supply a dry heat to the hollow side walls ; which

heat vrill enter the atmosphere round the plants by the openings ( / g) under the course

of tiles or slates (p). The moist heat, if desirable, might easily be admitted by direct

communications through the soil to the vault, made by a few bncks, a chimncy-pot, or a

whelmed flower-pot. Ventilators may be formed in the doors at each end for supplymg

cool air, in case of too great a heat in the v a u lt; and plugs or wooden blocks, with rings

for convement handling, may be placed in one or tivo places in the back and front walls,

to admit, through the hot vacuity, fresh air to the plauts in very severe weather. As the

outer surface of the end walls wiU be fully exposed to the weather, they should not

communicate with the side walls, but should form distmct hollow walls of themselves;

and, in order to prevent the escape of heat from the outer surface of the back and front

walis, a space, of a foot or more, between them and the soil in whicli they are sunk,

should be fiUed up with loose stones or brickbats (n).

2009. Tkompsoiis forcing pits (figs. 568, 569, and 570.) differ from those of M ‘Phail

by substituting stone lintels in place of pigeon-holes to the outside walls. The suspended

insulated position of the pits admits a circulation of warm air, both under and

all around the pit of each light, whereby a g-reatcr degree of surface temperature is

obtained, in the absence of solar rays, in the early forcing season. Fig. 568.: in the

ground-plan, a a a show the open-work end and the support for the north and south

lintels ; and b b h are bricks on edge, to support the bottom of the pits and the surface

hot-air flues round each. Fig. 569. is the longitudinal section : c c c c c are liot-air flues

round and under the bottom of the pit, which are covered with a single tile. Wlien the

bottom of the pit is laid, the brick on edge is continued up to a couveiiient lieight for

the surface hot-air flues, which are also covered with a single tile, laid the reverse way

to those at the bottom of the pit. Fig. 570. is the transverse section, showing the pits

and. the position of the lintels, wliich admit the fermenting body of manure to act under

the nortli and south flues. The internal pai't of the pits is covered with a thin coat of

hah* mortar, made rough by finishing it with a wood float and b ru sh ; and the tiles ave the

flat draining ones, without knobs. These pits arc generally from 5 ft. to 6 ft. 10 in. wide.

2010. Forman’s p it (fig. 571.) has the

floor for the tan or leaves (a ) supported

hy oak joists resting on the side walls,

and on a middle wall of open brickwork

(b). The joists are 3 in. deep, 1^ in.

thick, and 3 in. apart. Instead of being

covered with boards or tiles, a course of

tu rf is laid over them, which is found to

answer perfectly. The heated air is conveyed

from the chamber below into the

atmosphere of the plants by means of

small apertures (e) formed in the back and front walls, at 4^ in. a p a rt; and also through

tubes of iron, or chimney-pots (d), resting on the joists directly over the flue. Through

. M

( ■ ' f -I

i'. ' il

I' f: • -I