to be soured by the next day, at a suitable time for the churning. For the

churning and the working up of the butter there are employed the older so-

called Holstein churns and mechanial butter-workers, and also a newer type

of machine — a combined chum and butter-worker, this latter, apparently,

seeming to be rapidly ousting the oldfashioned apparatus, especially at the

larger dairies, where it greatly facilitates the working of the butter, lo r the

salting of the butter, the very finest-grained salt is used nowadays, m the

place of the relatively coarse-grained salt always recommended before. All the

butter intended for export is'packed in barrels, each containing preferably an

♦English hundredweight (centner).

Several inventors have endeavoured to construct machines to . skim and chum

at the same time. The only one of these machines that has come into any

use is the radiator, invented by E. 0 . N. Salenius. Its employment, however,

has not become very general, and, during the last few years, no new radia or-

dairies have been established. The radiator-dairies produce sweet-cream butter,

the greater part of which is sold within Sweden. I .

The gross price which milk — as a result of its employment for butter

manufacture - can fetch, depends, of course, on the percentage U K | |

the milk, and also on the price that can be had for the butter, skimmed milk,

and butter-milk, and can easily be calculated if these factors are known. But

from the gross price there have to be deducted the costs of manufacture, which

vary greatly with the different dairies, this depending upon local conditions and

also upon the size of the dairies. The expenses in question are lowest at the

largest dairies. According to the co-operative dairy-farming working statistics for j

1910, the expenses, apart from those for carriage, in the Lans of Malmohus

and Kristianstad amounted respectively to no more-than 4'97 and 5 06 kr per

1 000 kilograms milk, while in N o r r b o t t e n Lan, where the daily quantity of

milk per dairy amounted to only 902 kilograms, the expenses m question

rose to 14-28 kr. It is clear that such an increase m working ppenses!

must have a most injurious effect on the economy of the Q H B K ™

in thinly-populated parts of the country, where it is impossible to collect any

large quantity of milk without the costs for carnage becoming altogether too

heavy, it has, Consequently, been difficult to start a p a y i n g butter-making msi

ness. One method of solving the problem has been attempted, however, during

the last few years. At the close of the nineties there waa e stabli|ed §

Nybro, in Smaland, a dairy company based on the delivery da y j

cream’ i. e., a so-called “cream-dairy”. At Glimakra, in the northern part of j

Kristanstad Lan, a co-operative dairy was established in I®0.4*

system which proved a financial success and has had many imitators to

forest districts. These dairies were supplied with cream skimmed from the

at the farms of the various producers by means of hand-separators, B ' f f l

greatly facilitates transport, and other working expenses of the

become less. The type of dairy in question has one disadvantage howev J

for the cream skimmed at the farms H H always so wd l handled as oodd

wished, the result being that these dairies find ^ d ifficu lt Q B B K J

of uniformly good quality. It is' possible that this disadvantage could bj

avoided by establishing small skimming-stations around a central

dairy, but such a system is imaginable only on the supposition that th

ming-stations can be erected at sufficiently low cost. The plan appeals

have been made possible by the Balttoturbine dairying machine, g g W f l

on the market by the Baltic Co., Ltd. in 1911, and which is I B g

of boiler, a turbine-driven separator, regenerative-pasteunzmg

the necessary pumps, all driven by the separator-turbine. The whole mac | ;

occupies a floor-space of 1 ' iX l ' i square meters, and treats from 750

[kilograms of milk per hour. The dairying machine can also act as an in-

I dependent butter-dairy, as it is possible to connect it with a small chuming-

Bapparatus.

A not unimportant quantity of butter is made at the farms, both for home-

[consumption and also for sale; it is known as farm-butter (Sw. bondsmör). In

[tracts which are thinly populated and where ’’cream-dairies” have not as yet

¡ been established, hand-separators and hand-churns are still pretty extensively

Used. This is the case in a great part of Norrland, in Kopparberg Län, and

[in Göteborg och Bohus Län. In the latter län, dairy-farming on a large scale

¡has almost died out, partly as a result of this home-manufacture, and also in

[consequence of large amounts of milk being sent for direct consumption to

'Gothenburg, fishing-hamlets, stone-quarries, and sea-side places. In 1890, there

[were 32 dairies there, with a yearly milk-supply of 9 600 000 kilograms; in

1910, the number of dairies was only 5, and the amount of the milk treated

[but 2 200 000 kilograms.

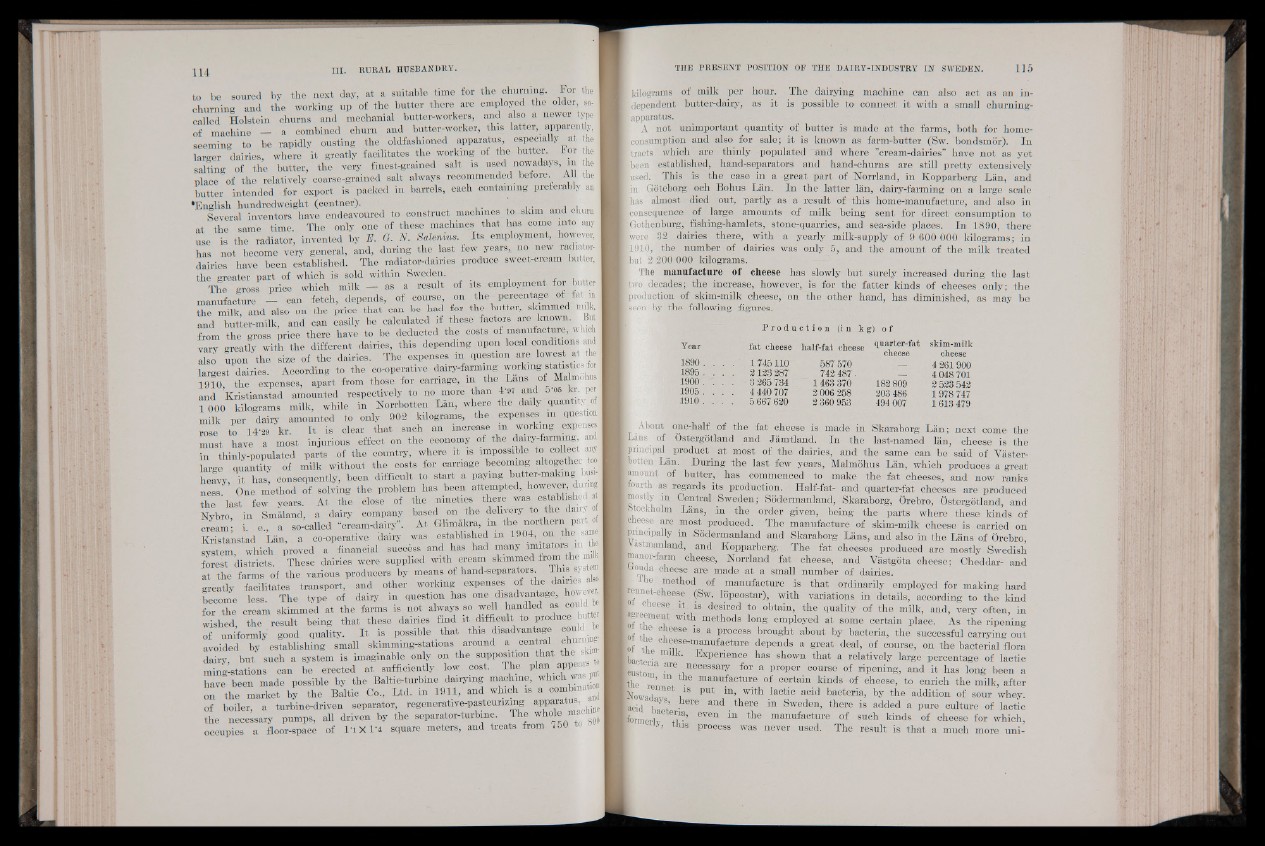

The manufacture of cheese has slowly but surely increased during the last

two decades; the increase, however, is for the fatter kinds of cheeses only; the

production of skim-milk cheese, on the other hand, has diminished, as may be

Been by the following figures.

P r o d u c t io n (in kg) o f

Year fat cheese half-fat cheese quarter-fat

cheese

skim-milk

cheese

1890 . . . . 1745110 587 570 ’ \ ^ 4 261900

1895 . . . . 2 123 287 742 487 . 4 048 701

1900 . . . 3 265 734 1463 370 182 809 2 523 542

1905 . . . 4 440 707 2 006 258 203 486 1 978 747

1910 . . . 5 667 620 2 360 953 494 007 1613 479

^ About one-half of the fat cheese is made in Skaraborg Lan; next come the

¡Lans of Ostergotland and Jamtland. In the last-named lan, cheese is the

principal product at most of the dairies, and the • same can be said of Vaster-

Botten Lan. During the last few years, Malmohus Lan, which produces a great

(amount, of butter, has commenced to make the fat cheeses, and now ranks

fourth as regards its production. Half-fat- and quarter-fat cheeses are produced

[mostly m Central Sweden; Sodermanland, Skaraborg, Örebro, Ostergotland, and

Stockholm Lans, in the order given, being the parts where these kinds of

{cheese are most produced. The manufacture of skim-milk cheese is carried on

principally in Sodermanland and Skaraborg Lans, and also in the Lans of Örebro,

jvastmanland, and Kopparberg. The fat cheeses produced are mostly Swedish

pnanor-farm cheese, Norrland fat cheese, and Vastgota cheese; Cheddar- and

|jouda cheese are made at a small number of dairies.

| ® method of manufacture is that ordinarily employed for making hard

ennet-ekeese (Sw. lopeostar), with variations in details, according to the kind

| cheese it. is desired to obtain, the quality of the milk, and, very often, in

i f methods long employed at some certain place. As the ripening

e cheese i s a process brought about by bacteria, the successful carrying out

:of I® eheese-manufacture depends a great deal, of course, on the bacterial flora

EacterLmi Experience has shown that a relatively large percentage of lactic

¡■custom .are neeessarY iff! a proper course of ripening, and it has long been a

fthe re’ . manufacture of certain kinds of cheese, to enrich the milk, after

iNowada i 1S PUt in> with lactic acid baeteria> by the addition of sour whey,

tcid b i t ■ and there ia Sweden, there is added a pure culture of lactic

fonnerlv 6Tei1 m the manufacture of such kinds of cheese for which,

y, this process was never used. The result is that a much more uni