coke quality, or to supersede wrought iron (Lancashire iron); in the latter

case it is applied to not very exacting purposes.

A- blast-furnace plant for coke is now being constructed at Oxelosund.

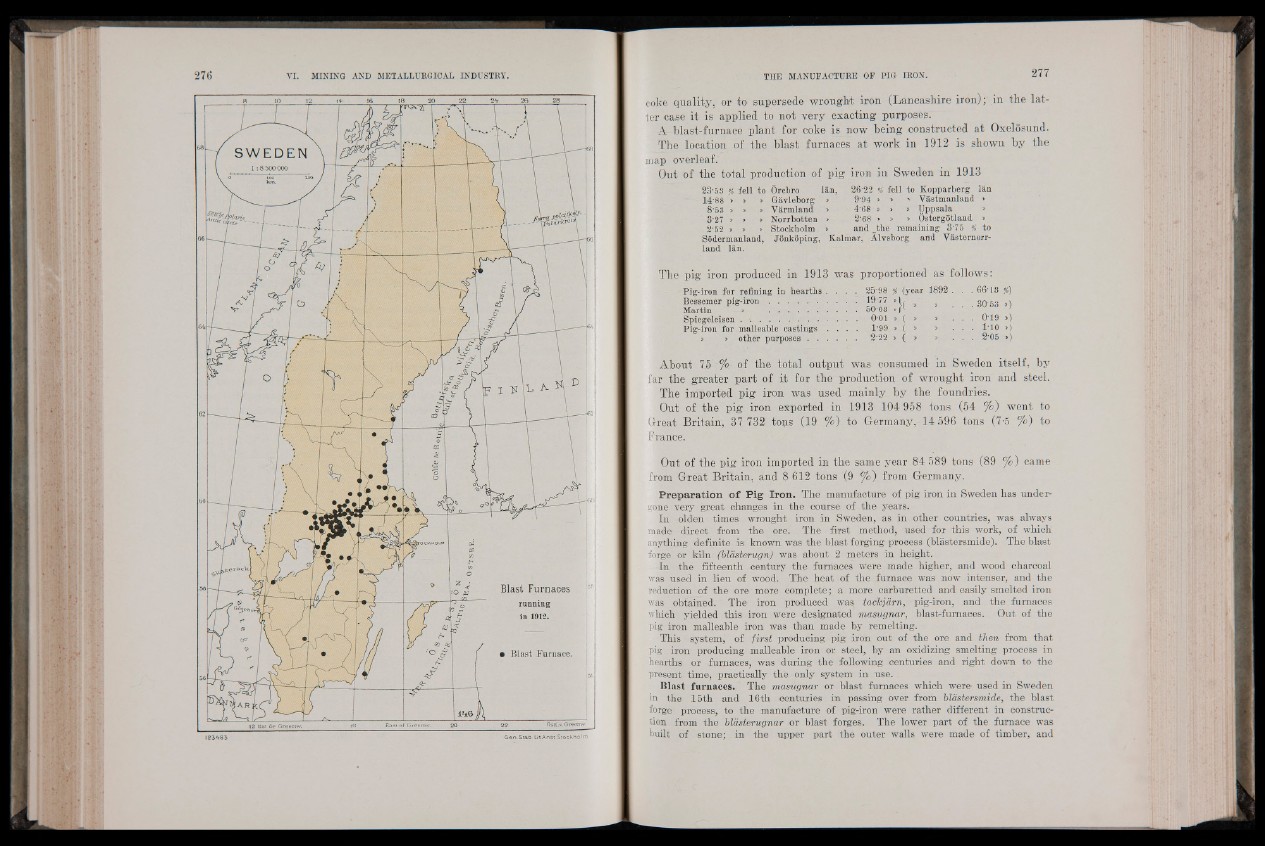

The location of the blast furnaces at work in 1912 is shown by the

map overleaf.

Out of the total production of pig iron in Sweden in 1913

23-53 ja fell to Örebro lan, 26*22 % fell to Kopparberg lan

14*88 * » » Gavleborg > 9*94 > > ■> Vastmanland >

853 » * > Yarmland » 4*68 » » > Uppsala »

3-27 » » » Norrbotten » 2*68 > > » Ostergotland >

2‘52 > » » Stockholm » and the remaining 375 % to

S'odermanland, Jdnkoping, Kalmar, Alvsborg and Yasternorr-

land lan.

The pig iron produced in 1913 was proportioned as follows:

Pig-iron for refining in heartbs . . . . 25*98 % (year 1892 . . . 66* 13 %)

Bessemer p ig -iro n 19*77 »1, , gg.gg .

Martin ...»......... ................................... 50*03 »0

Spiegeleisen . 0*01 » ( » | . . . 0*19 »)

Pig-iron for .malleable castings . . . . 1-99 > ( > j . . . 1*10 »)

i > other purposes...................... 2*22 » ( > > . . . 2*06 »)

About 7.5 of the total output was consumed in Sweden itself, by

far the greater part of it for the production of wrought iron and steel.

The imported pig iron was used mainly by the foundries.

Out of the pig iron exported in 1913 104 958 tons (54 %) went to

Great Britain, 37 732 tops (19 %) to Germany, 14 596 tons (7*5 %) to

France.

Out of the pig iron imported in the same year 84 589 tons (89 %) came

from Great Britain, and 8 612 tons (9 %) from Germany.

P r ep a ra tion o f P ig Iron. The manufacture of pig iron in Sweden has undergone

very great changes in the course of the years.

In olden times wrought iron in Sweden, as in other countries, was always

made direct from the ore. The first method, used for this work, of which

anything definite is known was the blast forging process (blastersmide). The blast

forge: or kiln (bldsterugn) was about 2 meters in height.

In the fifteenth century the furnaces were made higher, and wood charcoal

was used in lieu of wood. The heat of the furnace was now intenser, and the

reduction of the ore more complete; a more earburetted and easily smelted iron

was obtained. The iron produced was tacTcjarn, pig-iron, and the furnaces

which yielded this iron were designated masugnar, blast-furnaces. Out of the

pig iron malleable iron was than made by remelting.

This system, of first producing pig iron out of the ore and then from that

pig iron producing malleable iron or steel, by an oxidizing smelting process in

hearths or furnaces, was during the following centuries and right down to the

present time, practically the only system in use.

Blast furnaces. The masugnar or blast furnaces which were* used in Sweden

in the 15th and 16th centuries in passing over from blastersmide, the blast

forge process, to the manufacture of pig-iron were rather different in construction

from the blasterugnar or blast forges. The lower part of the furnace was

built of stone; .in the upper part the outer walls were made of timber, and