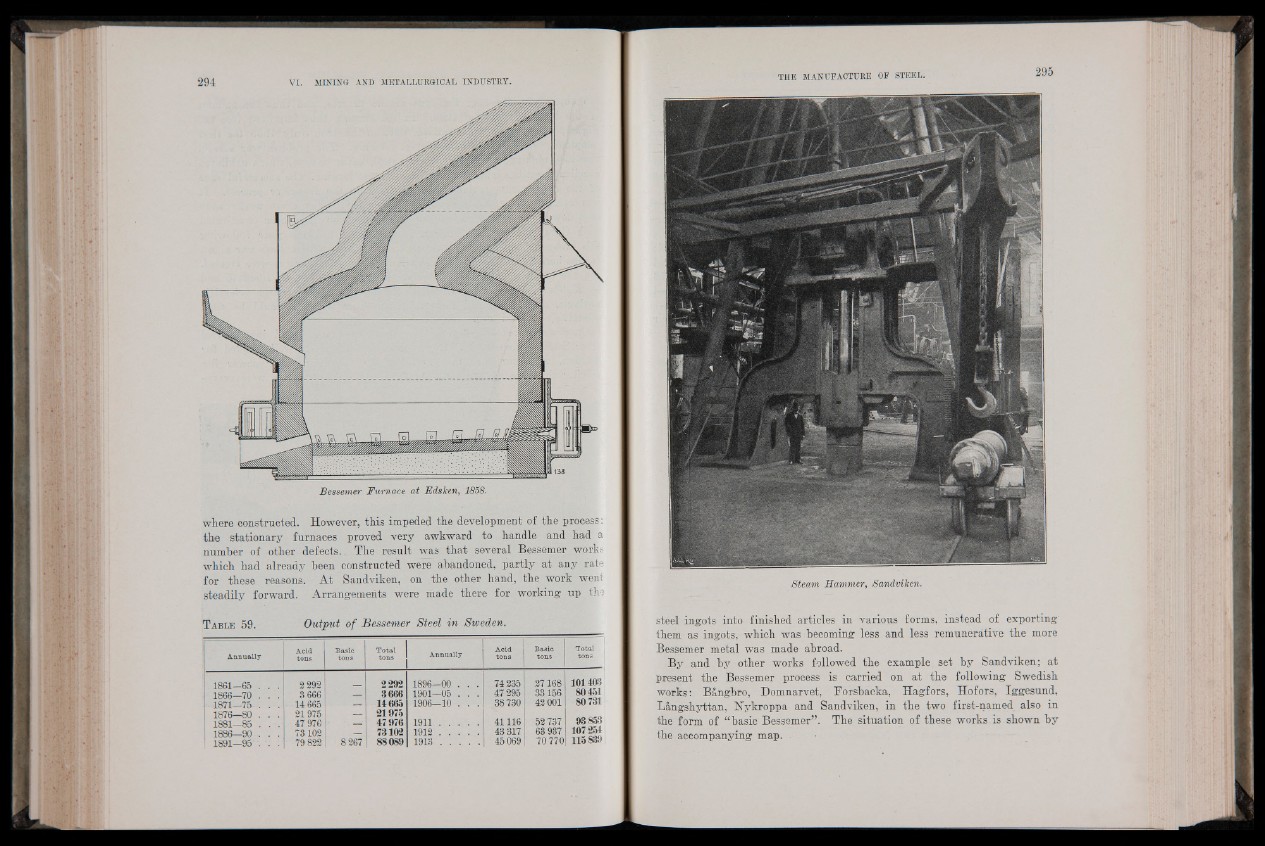

Bessemer Furnace at Edsken, 1858.

where constructed. However, this impeded the development of the process:

the stationary furnaces proved very awkward to handle and had a

number of other defects.. The result was that several Bessemer works

which had already been constructed were abandoned, partly at any rate

for these reasons. At Sandviken, on the other hand, the work went

steadily forward. Arrangements were made there for working up the

T able 59. Output of Bessemer Steel in Sweden.

Annually Acid

tons

Basic

toes

Total

tons Annually Acid

tons

Basic

tons

Total

tons

1861—65 . . . 2292 2292 1896—00 . . . 74 235 27168 101403

1866—70 . . . 3 666 _ 8 666 1901—05 . . 1 47 295 33156 80451

1871—75 . . . 14 665 — 14665 1906—10 . . . 38 730 42 001 80731

1876—80 . . .

21975

— 21975

1881—85 . . .

47 976

47 976 1 9 1 1 ................ 41116 52 737 93 853

1886—90 . . . 73 102 _ 73102 1 9 1 2 ................ 43 317 63 937 107 254

1 1891—95 . . . 79 822 8267 88089 1 9 1 3 ................ 45069 70 770 115 839

Steam Hammer, Sandviken.

steel ingots into finished articles in various forms, instead of exporting

them as ingots, which was becoming less and less remunerative the more

Bessemer metal was made abroad.

By and by other works followed the example set by Sandviken; at

present the Bessemer process is carried on at the following Swedish

works: Bangbro, Domnarvet, Borsbacka, Hagfors, Hofors, Iggesund,

Langshyttan, Nykroppa and Sandviken, in the two first-named also in

the form of “basic Bessemer”. The situation of these works is shown by

the accompanying map.