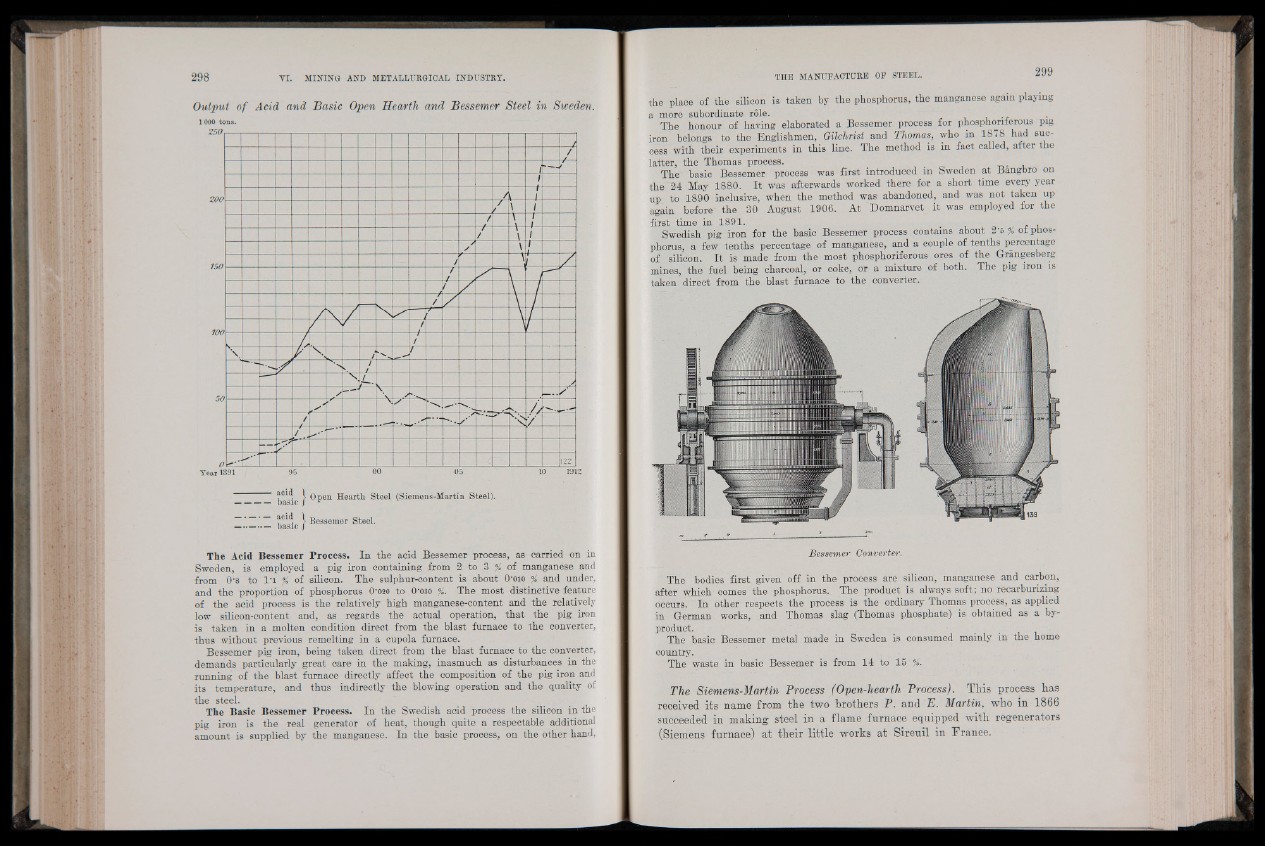

Output of Acid and Basic Open Hearth and Bessemer Steel in Sweden.

1 000 tons.

/

/

\

I

/ / 1 f \ 1

\ 1

1

/ \ 1

/ / \ 1

/ \

f/ ■r,

/ /

i / T”

/ 1 /

/ \ / / / /

\ / *s ■ j _—1/ *v s /// \ / /

y v— / r

/ Ü m /

/

122

T e ar 1891 95 00 05 10 1912

basic } ®Pei1 Hearth Steel (Siemens-Martin Steel).

— * “ ' basic 1j Bessemer Steel.

the place of the silicon is taken by the phosphorus, the manganese again playing

a more subordinate role.

The honour of having elaborated a Bessemer, process for phosphonferous pig

iron belongs to the Englishmen, Gilchrist and Thomas, who in 1878 had success

The Acid Bessemer Process. In the acid Bessemer process, as carried on in

Sweden, is employed a pig iron containing from 2 to 3 % of manganese and

from 0'8 to l ' l % of silicon. The sulphur-content is about O'oio % and under,

and the proportion of phosphorus 0'020 to O'030 %. The most distinctive feature

of the acid process is the relatively high manganese-content and the relatively

low silicon-content and, as regards the actual operation, that the pig iron

is taken in a molten condition direct from the blast furnace to the converter,

thus without previous remelting in a cupola furnace.

Bessemer pig iron, being taken direct from the blast furnace to the converter,

demands particularly great care in the making, inasmuch as disturbances in the

running of the blast furnace directly affect the composition of the pig iron and

its temperature, and thus indirectly the blowing operation and the quality of

the steel.

The Basic Bessemer Process. In the Swedish acid process the silicon in the

pig iron is the real generator of heat, though quite a respectable additional

amount is supplied by the manganese. In the basic process, on the other hand,

with their experiments in this line. The method is in fact called, after the

latter, the Thomas process. _

The basic Bessemer process was first introduced in Sweden at Bangbro on

the 24 May 1880. It was afterwards worked there for a short time every year

up to 1890 inclusive, when the method was abandoned, and was not taken up

again before the 30 August 1906. At "Domnarvet it was employed for the

first time in 1891.

Swedish pig iron for the basic Bessemer process contains about 2'6 % of phosphorus,

a few tenths percentage of manganese, and a couple of tenths percentage

of silicon. It is made from the most phosphoriferous ores of the Grangesberg

mines, the fuel being charcoal, or coke, or a mixture of both. The pig iron is

taken direct from the blast furnace to the converter.

Bessemer Converter.

The bodies first given off in the process are silicon, manganese and carbon,

after which' comes the phosphorus. The product is always soft; no recarburizing

occurs. In other respects the process is the ordinary Thomas process, as applied

in German works, and Thomas slag (Thomas phosphate) is obtained as a byproduct.

The basic Bessemer metal made in Sweden is consumed mainly in the home

country.

The waste in basic Bessemer is from 14 to 1 5 '

The Siemens-Martin Process (Open-hearth Process). This process has

received its name from the two brothers P . and E. Martin, who in 1866

succeeded in making steel in a flame furnace equipped with regenerators

(Siemens furnace) at their little works at Sireuil in France.