The leading idea of the Bessemer process is for the fining of the

pig iron to use only (1 ) the heat residing within the metal itself when

in a molten state (2 ) the heat generated when the blast sent through

the molten pig iron burns away the bodies (carbon, manganese, silicon,

phosphorus), which it is the object of the fining entirely or partially

to remove.

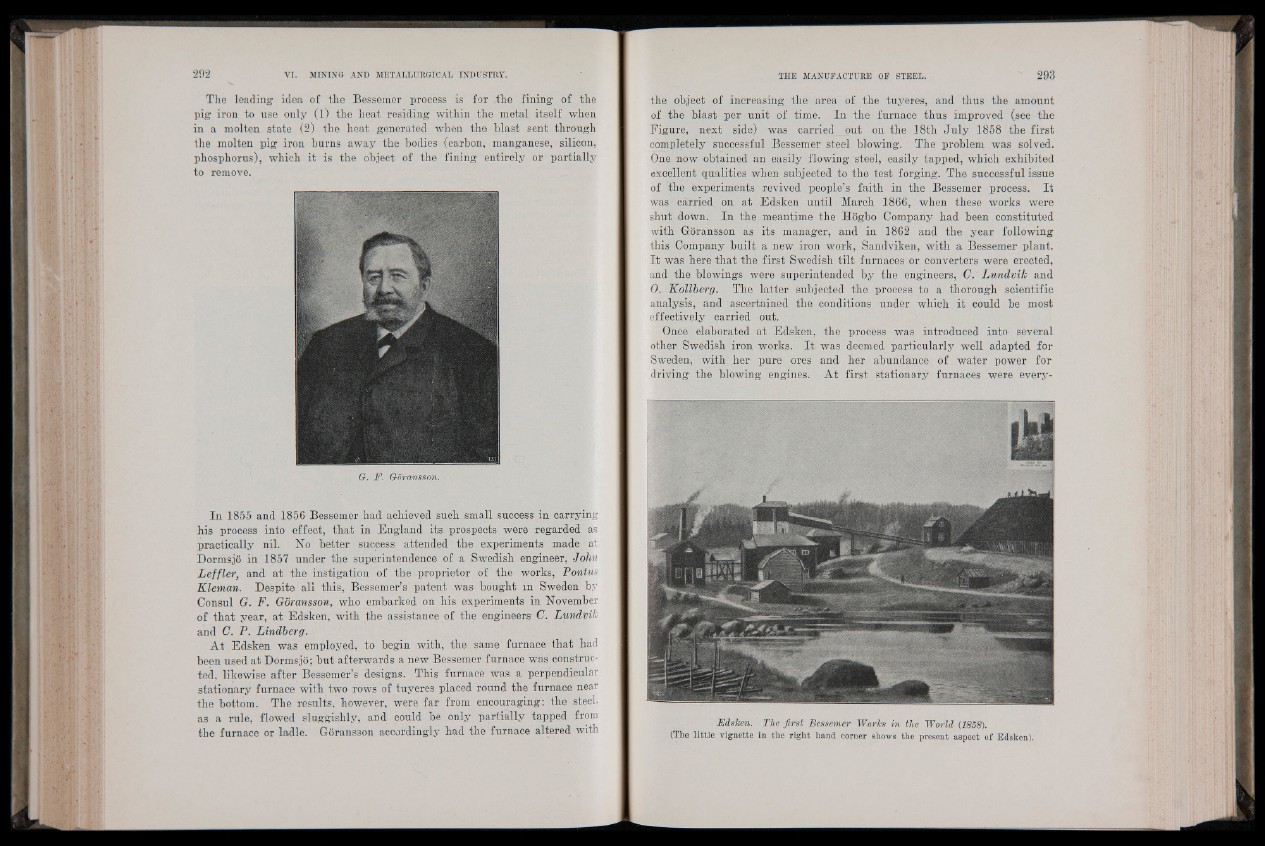

G. F. Goransson.

In 1855 and 1856 Bessemer had achieved such small success in carrying

his process into effect, that in England its prospects were regarded as

practically nil. No better success attended the experiments made at

Dormsjo in 1857 under the superintendence of a Swedish engineer, John

Leffler, and at the instigation of the proprietor of the works, Pontus

Kleman. Despite all this, Bessemer’s patent was bought m Sweden by

Consul G. F. Goransson, who embarked on his experiments in November

of that year, at Edsken, with the assistance of the engineers C. Lundvik

and C. P. Lindherg.

At Edsken was employed, to begin with, the same furnace that had

been used at Dormsjo; but afterwards a new Bessemer furnace was constructed,

likewise after Bessemer’s designs. This furnace was a perpendicular

stationary furnace with two rows of tuyeres placed round the furnace near

the bottom. The results, however, were, far from encouraging: the steel,

as a rule, flowed sluggishly, and could be only partially tapped from

the furnace or ladle. Goransson accordingly had the furnace altered with

the object of increasing the area of the tuyeres, and thus the amount

of the blast per unit of time. In the furnace thus improved (see the

Figure, next side) was carried out on the 18th July 1858 the first

completely successful Bessemer steel blowing. The problem was solved.

One. now obtained an easily flowing steel, easily tapped, which exhibited

excellent qualities when subjected to the test forging. The successful issue

of the experiments revived people’s faith in the Bessemer process. It

was carried on at Edsken until March 1866, when these works were

shut down. In the meantime the Hogbo Company had been constituted

with Goransson as its manager, and in 1862 and the year following

this Company built a new iron work, Sandviken, with a Bessemer plant.

It was here that the first Swedish tilt furnaces or converters were erected,

and the blowings were superintended by the engineers, C. Lundvik and

0. Kollberg. The latter subjected the process to a thorough scientific

analysis, and ascertained the conditions under which it could be most

effectively carried out.

Once elaborated at Edsken, the process was introduced into several

other Swedish iron works. It was deemed particularly well adapted for

Sweden, with her pure ores and- her abundance of water power for

driving the blowing engines. At first stationary furnaces were every

Edsken. The first Bessemer Works in the World (1858).

(The little vignette in the right hand comer shows the present aspect of Edsken).