100 000—150 000 volts. With this tension, transmission over a distance of some

500 kilometers can be effected, e. g., from Indalsalven to the middle of Sweden.

The cost would not work out particularly high per h. p., provided the energy

consumption called for were sufficiently great. The cost of transmission, relatively

to the power transmitted, appears from the appended diagram (based on

calculations by Centervall and Rossander). The cost is given in kronor per

kilo-watt (1 kilo-watt = 1*36 h. p.) per year, In these figures are included the

transformation cost at both ends of the line. The shape of the curves indicates

how the transmission- (and distribution-) cost rises when less considerable quantities

of power are transmitted.

The effective power-cost is the total of the transmission- and distribution-cost,

on the one hand, and the production-cost, on the other. In the case of Waterpower,

the production-cost involves interest on the value of the fall, interest on

and amortization of the money invested in the construction of the plant. Under

the conditions prevailing in Sweden, the construction-cost can, (according to

engineer Sven Liibeck) be estimated at an average of 2 5 0 ^ 3 5 0 kronor per h. p.,

giving an annual cost of 25 to -35 kr. per h. p. Thus the price of energy will

vary from a minimum of about 25 kr. per h. p., in the case of large supplies

for industrial purposes, to 100 kr. and more, in the case of small quantities of

distributed energy.

As a rule, the demand for energy from the consumers is not a constant one,

but varies from month to month and from hour to hour. A water-driven generating

plant, as a rule, is subject to considerable variation in the water-flow

according to the time of year. In order to secure something like correspondence^

between the demand for and the supply of power, it is necessary either to

regulate the water-flow — day-regulation by collecting the water in small reservoirs,

or year-regulation by damming the water up in large lakes l ||||o r the

station must be supplied with auxiliary machinery driven by power other than water.

Such auxiliary machinery also renders good service in the case of fault on the

transmission-line, when placed at the receiver end. Indeed, several of the plants

mentioned have erected auxiliary stations, generally steam-driven. Since the

production-cost of steam-power depends almost entirely on the cost of fuel,

while the cost¿ of water-power chiefly depends on the capacity of the station,

a combination of water-power for the normal load with steam-power for peakload

has been found to be a good economical arrangement. This is particularly

the case with central stations with light-load, such as communal stations. The

light-load generally has a “load-factor” of only about 1 500 hours out of the

8 760 hours of the year, and factories working during the day only require the

supply during 2 600 to 3 0 0 0 hours in the-year. Certain industries, again, such

as mills, wood-pulp mills, .etc. consume energy during nearly 7 000 hours in

the year. These facts, and what has been said above as to the cost of waterpower

as compared with steam-power, tend to show the economical advantages

of water-power in industrial development.

It is also clear from what has been said that water-power in use only for a

few hours of the year, as for electric lighting, agriculture, etc., will be rather

expensive. In these cases also the rather complicated and expensive distributing

systems must set limits to the use of water-power. In more populous districts,

however, it has been possible to establish such distribution with economic success,

and in several parts of the country electric energy is used for threshing,

pumping, etc., in a few cases, even for ploughing.

The use of electrical energy for electro-chemical purposes (see Electrochemical

Industry) and for electric smelting-furnaces for iron, steel, zinh, etc. is increasing

rapidly. For purely heating purposes, such as in houses, electricity is only suitable

where the energy can be obtained at a particularly low price (surplus energy).

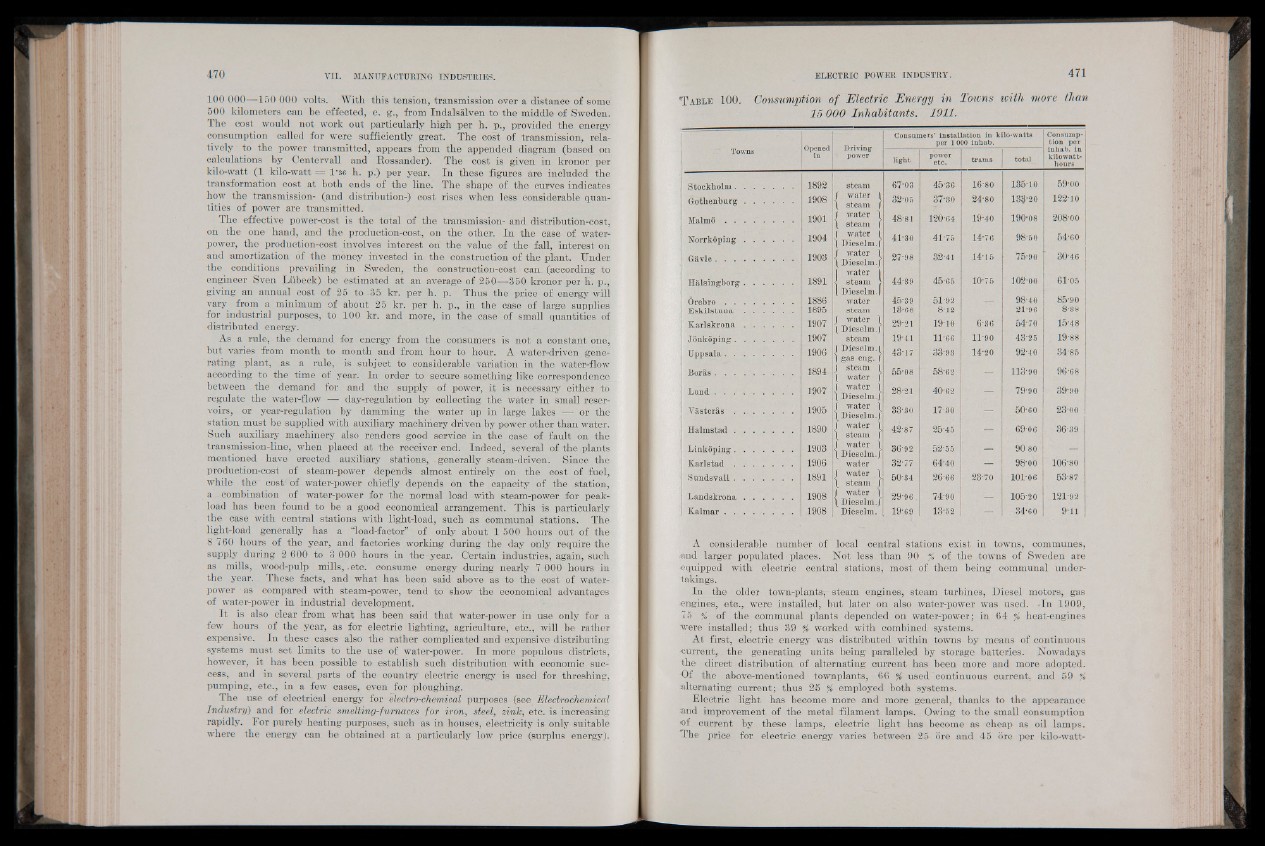

T able 100. Consumption of Electric Energy in Towns with more than

15 000 Inhabitants. 1911.

Consumers’ installation in kilo-watts ConsumpOpened

Driving

per 1 000 inhab. tion per

inhab. in

■ in power light power

etc. trams total kilowatthours

1892 steam 67-03 45-36 16-80 1 3 5 1 0 5 9 0 0

1908 f water 1

\ steam j 32-05 37-30 24-80 133-20 122-10

1901 1 water 1

\ steam j 4 8 8 1 120-64 19-40 190-08 208-00

1904 1 water 1

\ Dieselm.j 41:30 41-75 14-76 98-50 54-60

1903 j water 1

\ Dieselm. j

| water 1

27-98 32-41 1 4 1 5 75-90 3 0 46

1891 < steam >

I Dieselm. J

44-39 45-65 1 0 :75 102-00 6 1 0 5

1886 water 45-39 51-92 98-40 85-90

1895 steam 13-68 8-12 21-96 8-38

1907 J water 1

\ Dieselm.j 29-21 19-10 6-36 54-70 15-48

1907 steam 19-41 11-66 ■ 11-90 4 3 2 5 19-88

1906 1 Dieselm. I

\ gas eng. J 43-17 33-93 14-20 92-40 34-85

1894 j steam 1 55-08 58-62 1 \ water J 113-90 96-68

1907 i water \

\ Dieselm.j 28-21 40-62 — 79-90 39-90

1905 ( water (

\ Dieselm./ 38-30 17-30 50-60 23-00

1890 j water 1

\ steam j 42-87 25-45 — 69-06 36-39

1903 i water \

\ Dieselm.j 36-92 52'55 í t— ¡ 90 80 — ■

1906 water 32-77 64-40 98-00 106-80

1891 f water 1

\ steam J 50-34 26;66 23-70 101-06 53-87

19Q8 1 water 1

\ Dieselm.j 2 9-96. 74:90 _ 105-20 121-92

1908 Dieselm. 19,69 13-52 n 34-60 9-11

Stockholm.

Gothenburg

Malmo . .

Norrkoping

Gavle . . .

Halsingborg

Örebro . .

Eskilstuna

Karlskrona

Jonkoping.

Uppsala. .

Bor&s. . .

Lund . . .

Vaster&s .

Ilalmstad .

Linköping .

Karlstad .

Sundsvall .

Landskrona

Kalmar . .

A considerable number of local central stations exist in towns, communes,

and larger populated places. Not less than 90 % of the towns of Sweden are

•equipped with electric central stations, most of them being communal undertakings.

In the older town-plants, steam engines, steam turbines, Diesel motors, gas

engines, ete., were installed, but later on also water-power was used. -In 1909,

75 % of the communal plants depended on water-power; in 64 % heat-engines

were installed; thus 39 % worked with combined systems.

At first, electric energy was distributed within towns by means of continuous

-current, the generating units being paralleled by storage batteries. Nowadays

the direct distribution of alternating current has been more and more adopted.

■Of the above-mentioned townplants, 66 % used continuous current, and 59 %

alternating current; thus 25 % employed both systems.

Electric light has become more and more general, thanks to the appearance

and improvement of the metal filament lamps. Owing to the small consumption

of. current by these lamps, electric light has become as cheap as oil lamps.

The price for electric energy varies between 25 ore and 45 ore per kilo-watt