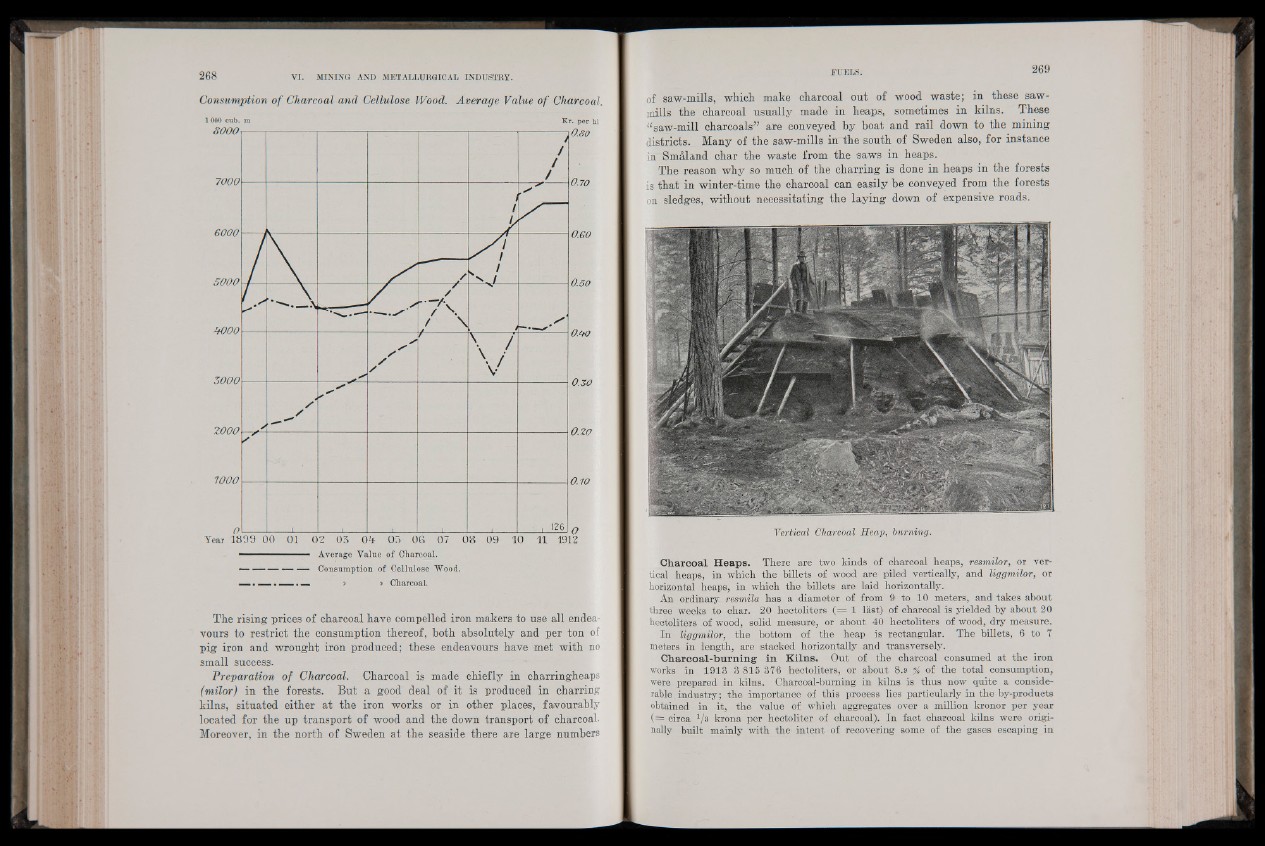

Consumption of Charcoal and Cellulose Wood. Average Value of Charcoal.

1 000 cub. m

Kr. per hi

8 0 0 0 \

700 0

6 0 0 0

5 0 0 0

OOOO

5 0 0 0

2000

1000

/

/

/

/

/L

s

/ 1

S i

/ /

v /

1 mm

*■— /

/ /

m ! ____1

p i

/ / / /

/

y

/ m pS «-o'

gg

✓

1 1 , 126

Tear 1899 00 01 02 03 Oh 05 OG 07 08 09 10 11 1912

■ Average Value of Charcoal.

----------------- Consumption of Cellulose "Wood.

The rising prices of charcoal have compelled iron makers to use all endeavours

to restrict the consumption thereof, both absolutely and per ton of

pig iron and wrought iron produced; these endeavours have met with no

small success.

Preparation of Charcoal. Charcoal is made chiefly in okarringheaps

(milor) in the forests. But a good deal of it is produced in charring

kilns, situated either at the iron works or in other places, favourably

located for the up transport of wood and the down transport of charcoal.

Moreover, in the north of Sweden at the seaside there are large numbers

of saw-mills, which make charcoal out of wood waste; in these sawmills

the charcoal usually made in heaps, sometimes in kilns. These

“saw-mill charcoals” are conveyed by boat and rail down to the mining

districts. Many of the saw-mills in the south of Sweden also, for instance

in Smaland char the waste from the saws in heaps.

The reason why so much of the charring is done in heaps in the forests

is that in winter-time the charcoal can easily he conveyed from the forests

on sledges, without necessitating the laying down of expensive roads.

Vertical Charcoal Heap, burning.

Charcoal Heaps. There are two kinds bf charcoal heaps, resmilor, or vertical

heaps, in which the billets of wood are piled vertically, and liggmilor, or

horizontal heaps, in which the billets are laid horizontally.

An ordinary resmila has a diameter of from 9 to 10 meters, and takes about

three weeks to char. 20 hectoliters ( = 1 last) of charcoal is yielded by about 20

hectoliters of wood, solid measure, or about 40 hectoliters of wood, dry measure.

In liggmilor, the bottom of the heap is rectangular. The billets, 6 to 7

meters in length, are stacked horizontally and transversely.

Charcoal-burning in Kilns. Out of the charcoal consumed at the iron

works in 1913 3 815 376 hectoliters, or about 8.9 % of the total consumption,

were prepared in kilns. Charcoal-burning in kilns is thus now quite a considerable,

industry; the importance of this process lies particularly in the by-products

obtained in it, the value of which aggregates over a million kronor per year

( = circa V3 krona per hectoliter of charcoal). In fact charcoal kilns were originally

built mainly with the' intent of recovering some of the gases escaping in