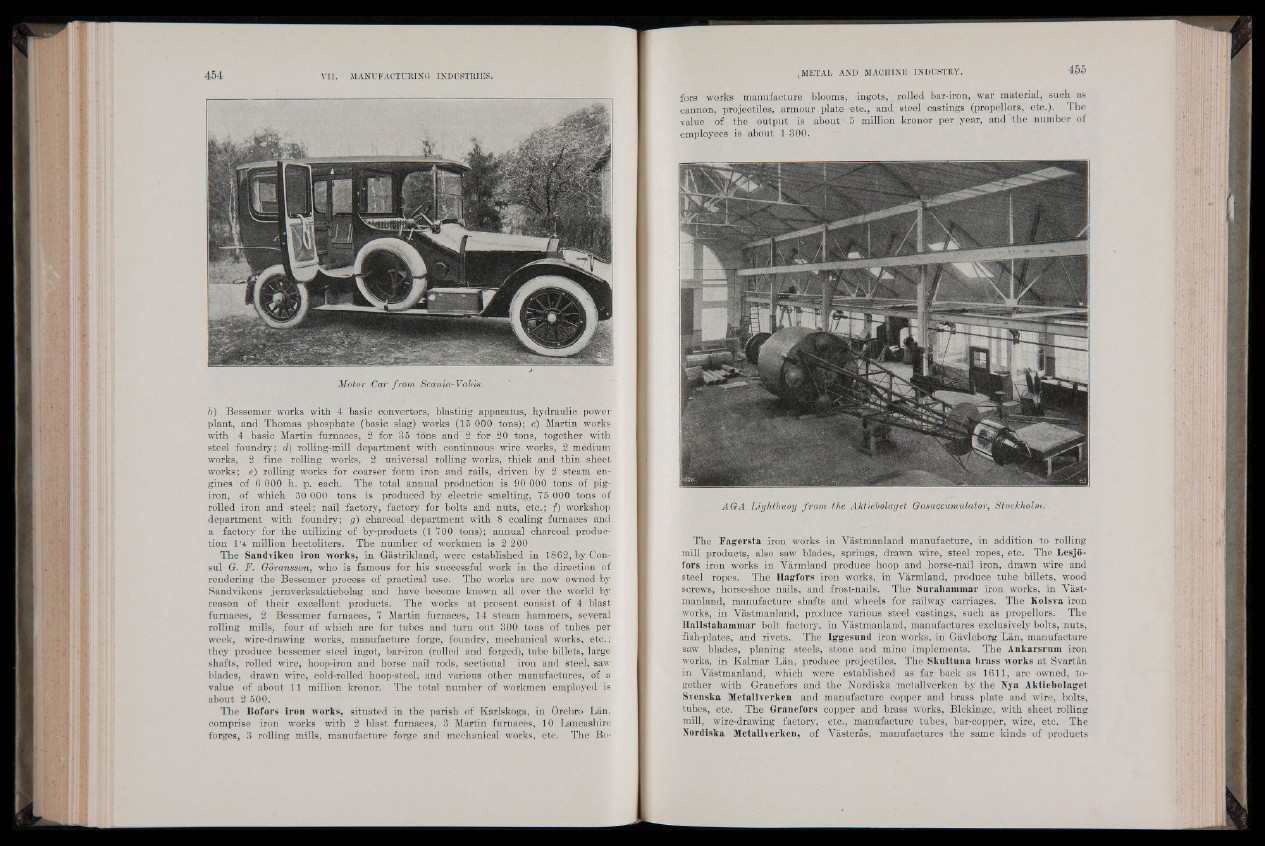

Motor Car from Scania-Vabis.

b) Bessemer works with 4 basic convertors, blasting apparatus, hydraulic power

plant, and Thomas phosphate (basic slag) works (15 000 tons); c) Martin works

with 4 basic Martin furnaces, 2 for 85 tons and 2 for 20 tons, together with

steel foundry; d) rolling-mill department with continuous wire works, 2 medium

works, 2 fine rolling works, 2 universal rolling works, thick and thin sheet

works; e) rolling works for coarser form iron and rails, driven by 2 steam engines

of 6 000 h. p. each. The total annual production is 90 000 tons of pig-

iron, of which 80 000 tons, is produced by electric smelting, 75 000 tons of

rolled iron and steel; nail factory, factory for bolts and nuts, etc.; f) workshop

department with foundry; g) charcoal department with 8 coaling furnaces and

a factory for the utilizing of by-products (1 700 tons); annual charcoal production

1*4 million hectoliters. The number of workmen is 2 200

The Sandviken iron works, in Gastrikland, were established in 1862, by Consul

G. F. Goransson, who is famous for his successful work in the direction of

rendering the Bessemer process of practical use. The works are now owned by

Sandvikens jernverksaktiebolag and have become known all over the world by

reason of their excellent products. The works at present consist of 4 blast

furnaces, 2 Bessemer furnaces, 7 Martin furnaces, 14 steam hammers, several

rolling mills, four of which are for tubes and turn out 300 tons of tubes per

week, wire-drawing works, manufacture forge, foundry, mechanical works, etc.;

they produce bessemer steel ingot, bar-iron (rolled and forged), tube billets, large

shafts, rolled wire, hoop-iron and horse nail rods, sectional iron and steel, saw

blades, drawn wire, cold-rolled hoop-steel, and various other manufactures, of a

value of about 11 million kronor. The total number of workmen employed is

about 2 500.

The Bofors iron works, situated in the parish of Karlskoga, in Örebro Lan,

comprise iron works with 2 blast furnaces, 3 Martin furnaces, 10 Lancashire

forges, 3 rolling mills, manufacture forge and mechanical works, etc. The Bofors

works manufacture blooms, ingots, rolled bar-iron, war material, such as

cannon, projectiles, armour plate etc., and steel castings (propellors, etc.). The

value of the output is about * 5 million kronor per year, and the number of

employees is about 1 300.

AG A Lightbuoy from the Aktiebolaget Gasaccumulator, Stockholm.

The Fagersta iron works in Vastmanland manufacture, in addition to rolling

mill products, also saw blades, springs, drawn wire, steel ropes, etc. The Lesjo-

fors iron works in Varmland produce hoop and horse-nail iron, drawn wire and

steel ' ropes. The Hagfors iron works, in Varmland, produce tube billets, wood

screws, horse-shoe nails, and frost-nails. The Surahammar iron works, in Vastmanland,

manufacture shafts and wheels for railway carriages. The Kolsva iron

works, in Vastmanland, produce various steel castings, such as propellors. The

Hallstaharnmar bolt factory, in Vastmanland, manufactures exclusively bolts, nuts,

fish-plates, and rivets. The Iggesund iron works, in Gavleboig Lan, manufacture

saw blades, planing steels, stone and mine implements. The Ankarsruin iron

works, in Kalmar Lan, produce projectiles. The Skultuna brass works at Svartan

in Vastmanland, which were established as far back as 1611, are owned, together

with Granefors and the Nordiska metallverken by the Nya Aktiebolaget

Svenska Metallverken and manufacture copper and brass plate and wire, bolts,

tubes, etc. The Granefors copper and brass works, Blekinge, with sheet rolling

mill, wire-drawing factory, etc., manufacture tubes, bar-copper, wire, etc. The

Nordiska Metallverken^ of Vasteras, manufactures the same kinds of products