a worsted spinning-mill. There are also a number of spinning-mills in the

rural districts, mainly for the treatment of native wool.

The number of spindles in the Swedish woollen industry amounted in

1912 to about 240 000 and the number of looms to 5 000. Among the

most remarkable features of this industry in later times may be mentioned

the growing employment of ring-spindle looms in the carding-wool

industry, although mostly for the coarser yarns; further, the so-called

dyeing of felling — previously introduced into the cotton industry, and,

finally, the general introduction into the mills, of the two-loom system

and quick-working looms, this making possible an essential increase in the

output.

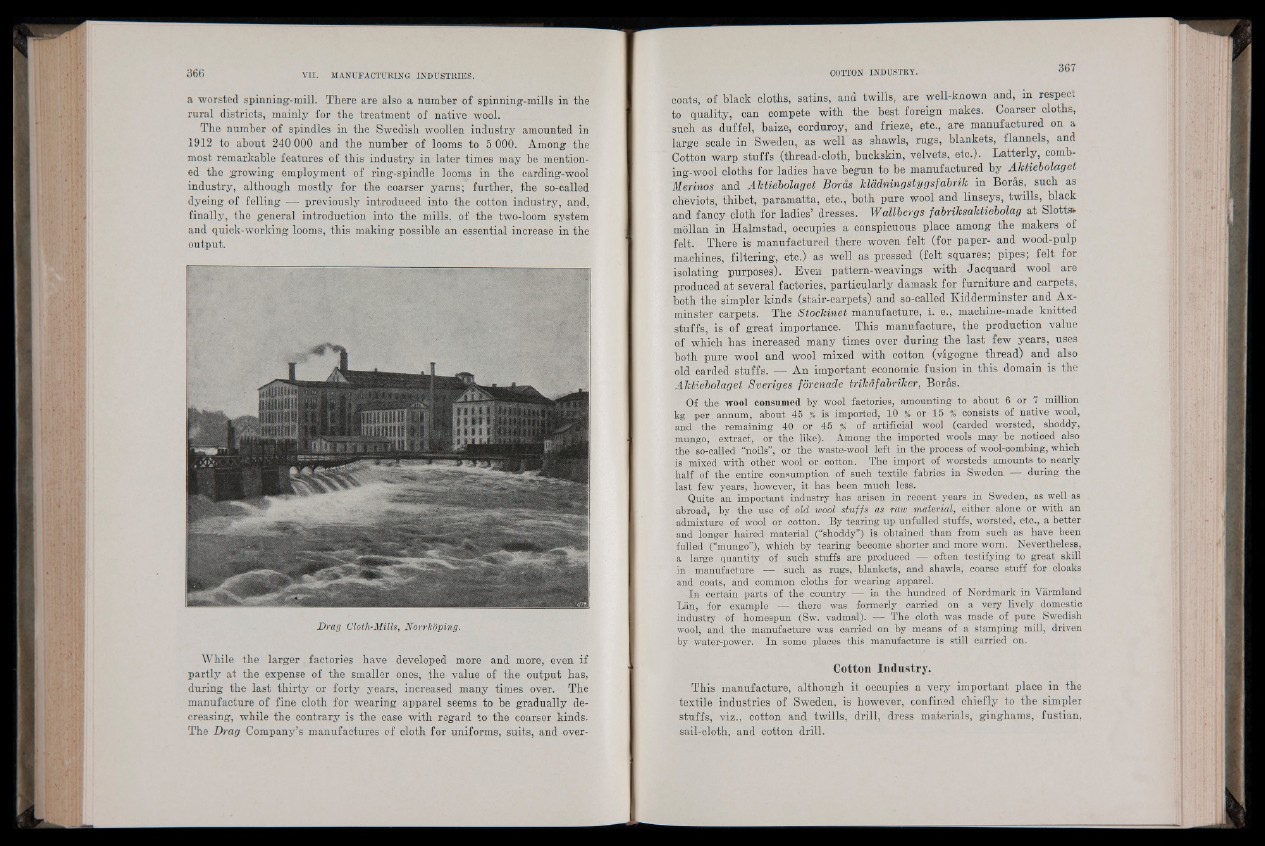

Drag Cloth-Mills, Norrhoping.

While the larger factories have developed more and more, even if

partly at the expense of the smaller ones, the value of the output has,

during the last thirty or forty years, increased many times over. The

manufacture of fine cloth for wearing apparel seems to be gradually decreasing,

while the contrary is the case with regard to the coarser kinds.

The Drag Company’s manufactures of cloth for uniforms, suits, and overcoats,

of black cloths, satins, and twills, are well-known and, in respect

to quality, can compete with the best foreign makes. Coarser cloths,

such as duffel, baize, corduroy, and frieze, etc., are manufactured on a

large scale in Sweden, as well as shawls, rugs, blankets, flannels, and

Cotton warp stuffs (thread-cloth, buckskin, velvets, etc.). Latterly, comb-

ing-wool cloths for ladies have begun to be manufactured by Ahtiebolaget

Merinos and Alctiebolaget Boras kladningstygsfabrik in Boras, such as

cheviots, thibet, paramatta, etc., both pure wool and linseys, twills, black

and fancy cloth for ladies’ dresses. Wallbergs fabriksaktiebolag at Slotta*

mollan in Halmstad, occupies a conspicuous place among the makers of

felt. There is manufactured there woven felt (for paper- and wood-pulp

machines, filtering, etc.) as well as pressed (felt squares; pipes; felt for

isolating purposes). Even pattern-weavings with Jacquard wool are

produced at several factories, particularly damask for furniture and carpets,

both the simpler kinds (stair-carpets) and so-called Kidderminster and Ax-

minster carpets. The Stockinet manufacture, i. e., machine-made knitted

stuffs, is of great importance. This manufacture, the production value

of which has increased many times over during the last few years, uses

both pure wool and wool mixed with cotton (vigogne thread) and also

old carded stliffs. — An important economic fusion in this domain is the

Ahtiebolaget Sveriges fôrenade trikafabriher, Boras.

Of the wool consumed by wool factories, amounting to about 6 or 7 million

kg per . annum, about 45 % is imported, 10 % or 15 % consists of native wool,

and the remaining 40 or 45 % of artificial wool (carded worsted, shoddy,

mungo, extract, or the like). Among the imported wools may be noticed also

the so-called “noils”, or the waste-wool left in the process of wool-combing, which

is mixed with other wool or cotton. The import of worsteds amounts to nearly

half of thé entire consumption of such textile fabrics in Sweden — during the

last few years, however, it has been much less.

Quite, an important industry has arisen in recent years in Sweden, as well as

abroad, -by the use of old wool stuffs as raw material, either alone or with an

admixture of wool or cotton. By tearing up unfulled stuffs, worsted, etc., a better

and longer haired material (“shoddy”) is obtained than from such as have been

fulled (“mungo”), which by tearing become shorter and more worn. Nevertheless,

a large quantity of such stuffs are produced IJfgoften testifying to great skill

in manufacture — such as rugs, blankets, and shawls, coarse stuff for cloaks

and coats, and common cloths for wearing apparel.

J-n- certain parts of the . country i f in the hundred of Nordmark in Varmland

Lan, for example — there was formerly carried on a very lively domestic

industry of homespun (Sw. vadmal). S - The cloth was made of pure Swedish

wool, and the manufacture was carried on by means of a stamping mill, driven

by water-power. In some places this manufacture is still carried on.

Cotton Industry.

This manufacture, although it occupies a very important place in the

textile industries of Sweden, is however, confined chiefly to the simpler

stuffs, viz., cotton and twills, drill, dress materials, ginghams, fustian,

sail-cloth, and cotton drill.