Candles.

Up to about the year 1860, wax caudles and “steeples” and tallow caudles

were almost the only kind of artificial light, for, though colza-oil lamps attained

a certain degree of popularity, the tallow candles dipped at home were and

remained indispensable in every household, until the time when gas and American

petroleum almost simultaneously became known and brought into use. In

place of tallow candles, stearine candles are now almost universally employed,

and in recent years, composition candles (of stearine and paraffine wax) or, more

seldom in Sweden, candles of paraffine wax, in cases where, for some reason,

candle light is preferred or must be used. The manufacture of stearine candles

in Sweden dates from 1841, when L. J. Hierta, a prominent and active man

in many directions, in conjunction with J. Michaelson, established the factory at

Liljeholmen. In 1843, Lars Montón founded the Clara candle-factory, the second

of the kind in the country. In 1912, Sweden had five stearine candle factories,

with 369 workmen and an output of 22 823 quintals of candles, valued at

1 9 7 5 000 kronor, mostly of pure stearine. Besides this, in both the stearine

factories of Liljeholmen and Clara, the by-products glycerine and oleine were

obtained to a value of 502 000 and 596 000 kronor respectively. The import

of candles in 1913 amounted to 20 600 kronor, of glycerine to 445 000 kronor,

of oleine to 457 000 kronor, and of stearine to 127 000 kronor. The exports were

37 500, 185 000, and 144 000 kronor respectively.

In the manufacture of stearine candles, certain fatty substances are used for

raw material, such as tallow and various oils consisting of a mixture n f fluid

and solid fat, chiefly oleine, palmitine, and stearine. In the manufacture of

candles, these so-called neutral fats are decomposed by the actions of some base,

such as lime, magnesia, or oxide of zinc, under pressure or with concentrated

sulphuric acid, and during recent years in an emulsion with diluted acid, into

glycerine and oleine, palmitic and stearic acids. Oleic acid is fluid at ordinary

temperatures, palmitic and stearic acids, on the other hand, are solid, and, after

due purifying, these are employed in the moulding of candles. The by-products

in candle-making, glycerine and oleic acid (oleinel, are collected and purified

separately. Glycerine is utilized in a large variety of ways, as a medical agent,

but chiefly for cosmetics and for nitro-glycerine. 0\eine (oleic acid, as it ;is incorrectly

named in the trade) is employed both in the manufacture of hard and

soft soap, and as a dressing agent for wool in the textile industry.

The consumption of candles in Sweden may be seen from the following figures:

Annually 7 Kg

1881-85 .................................... 1481000

1886—90 ................................................ 1 578 000 ,

1891—95 ............................................... 1761000

1896—00 ............................................ . 2067 000

1901—05 ................................ 2 454 000

1906—10 ................................................ 2 407 000

1910 ........................................ 2503 000

1911 ....................................................... 2 211000

1912 ....................................................... 2 239 000

1913 ....................... . 2 415 000

Scents.

Scents, in the ordinary sense, are most frequently solutions of fragrant substances

in pure spirit. In general, scents and the choicer soaps are made in the

same factories. The whole output of scent was valued at 1 107 000 kronor in

1912, and the export at 100 000 kronor. The number of factories was 23

employing 81 hands, in 1912.

Hard and Soft Soaps

are obtained by the decomposition of different kinds of fat, both solid and fluid,

by means of alkalies. Generally speaking, hard soap is soda, soft soap, potash,

chemically combined with fatty acids.to form salts. The boiling of hard soap,

like so many processes, used to be done on a small scale to supply domestic

needs; from wood-ashes and lime was obtained the required potash lye, which

was boiled with an admixture of tallow. A soft tallow soap was the result, from

Which, by the addition of common salt, a firm and good hard tallow-soap was

obtained. The first soft-soap factory in Sweden was founded in 1823 by Lars

Monten, in co-operation with the famous chemist, Berzelius. Though the raw

materials for this industry, especially tallow, linseed oil, and train-oil, might

partly be obtained in the country itself, the greater proportion of the raw materials

used are now brought from abroad, because the home- production is insufficient,

more especially since certain oils obtained from tropical plants, such

as cocoa-nut oil, palm-oil, etc., have begun to be used in soap-making. Soft

soap used to be generally employed for washing, but has latterly been superseded

by hard soap. Bor cheap toilet soaps, cocoa-nut oil is primarily made use of.

Soaps have also been recently manufactured by taking, first of all as neutral

a soap as possible,: and grinding, perfuming, and pressing it. Besides other

good qualities possessed by soaps prepared by this method they also admit of

being scented better and more lastingly than others.

The production of soft and hard soaps has made great .progress in Sweden

during the last 50 years. In 1860, there were 13 factories producing 2 105 000

kg of a value of 859 000, kronor.

In 1912 there were 60 factories, employing 745 workmen and producing

24 472 000 kg, valued at 10 236 000 kronor.

The consumption of cleansing materials, which is considered as a standard of

civilization, has increased about seven times per person and per annum in Sweden,

in spite of the fact that alkalies are now much used directly for cleaning purposes.

The price of soft soap and hard soap has, on an average remained the

same as then, 40'8 and 41 ’8 ore pr kg. respectively but for hard soap alone it

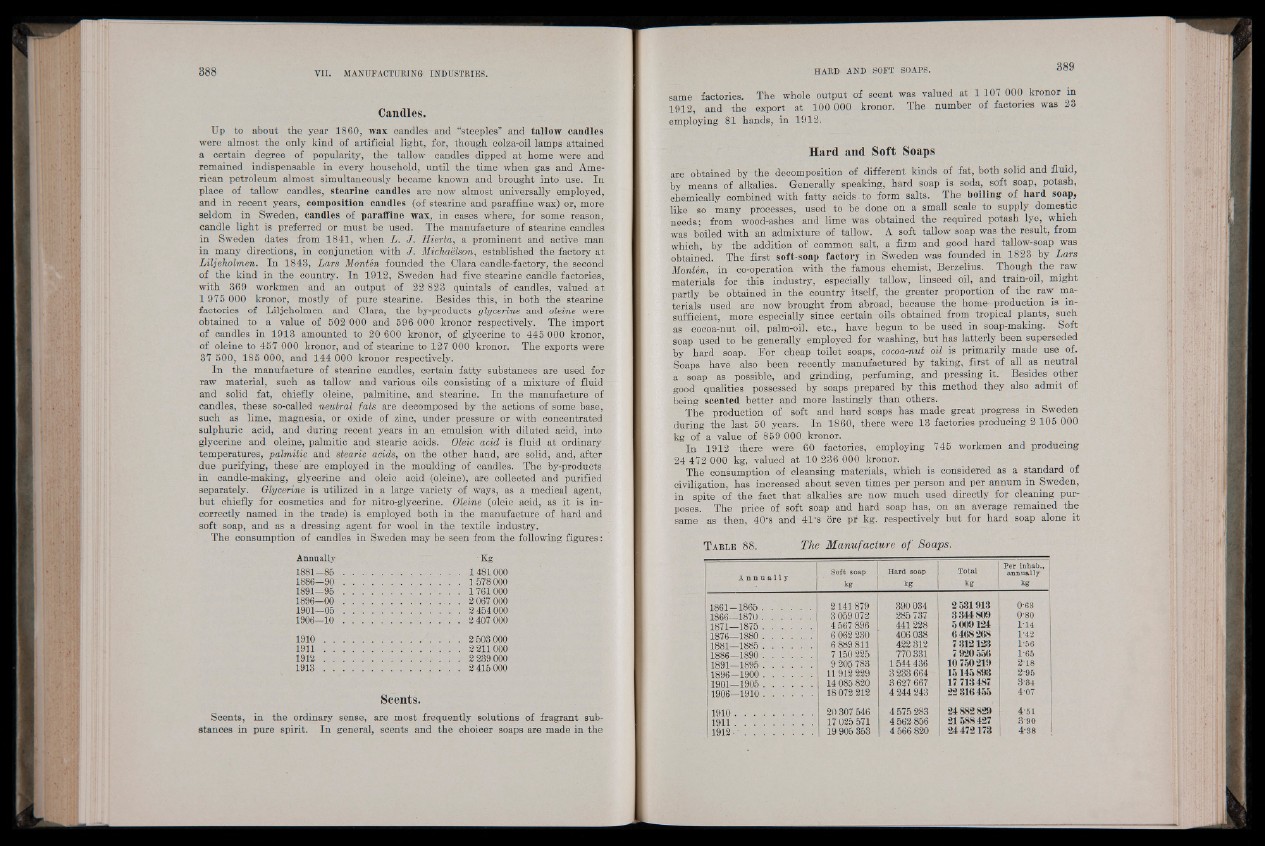

T ab le 88. The Manufacture of Soaps.

A n n u a l i y

Soft soap

kg

Hard soap

kg

Total

kg

Per inhab.,

annually

kg

1861 1865 . . . . . . 2 141 879 390 034 2531913 0-63

1866—1870 .................... 3 059 072 285 737 3344 809 080

1871—1875 .................... 4 567 896 441 228 5009124 H k

1876—1880 ................ 6 062 230 406 038 6468268 1-42

1881—1885 .................... 6 889 811 422 312 7 312123 1-56

1886-1890 .................... 7 150 225 770 331 7 920 556 1-65

1891—1895 | ................ 9 205783 1544 436 10 750 219 218

1896-1900 .................... 11 912 229 3 233 664 15 145 893 2'95

1901—1905 .................... 14 085 820 3 627 667 17 713487 3-34

1906 1910 .................... 18072 212 4 244 243 22316455 4-07

1910 20 307 546 4 575 283 24 882 829 4-51

1911............................... 17 025 571 4 562 856 21588427 3-90

1 9 1 2 . . . . . . . . 19 905 353 4 566 820 24 472173 4'38