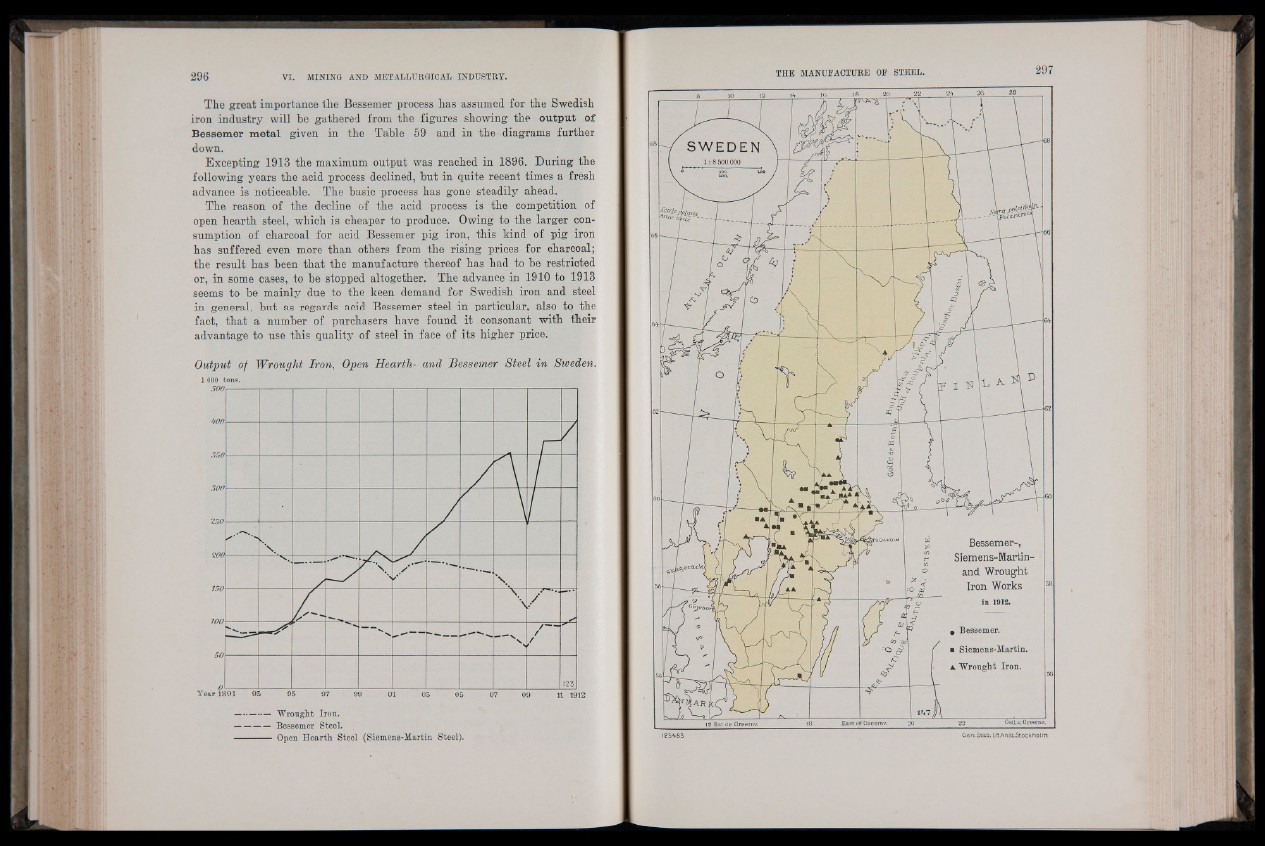

The great importance the Bessemer process has assumed for the Swedish

iron industry will be gathered from the figures showing the output o f

Bessemer metal given in the Table 59 and in the diagrams further

down.

Excepting 1913 the maximum output was reached in 1896. During the

following years the acid process declined, hut in quite recent times a fresh

advance is noticeable. The basic process has gone steadily ahead.

The reason of the decline of the acid process is the competition of

open hearth steel, which is cheaper to produce. Owing to the larger consumption

of charcoal for acid Bessemer pig iron, this kind of pig iron

has suffered even more than others from the rising prices for charcoal;

the result has been that the manufacture thereof has had to be restricted

or, in some Cases, to be stopped altogether. The advance in 1910 to 1913

seems to be mainly due to the keen demand for Swedish iron and steel

in general, but as regards acid Bessemer steel in particular, also to the

fact, that a number of purchasers have found it consonant with their

advantage to use this quality of steel in face of its higher price.

Output of Wrought Iron, Open Hearth- and Bessemer Steel in Sweden.

1 000 tons.

Wrought Iron.

-------------Bessemer Steel.

Open Hearth Steel (Siemens-Martin Steel).