million tons of peat for fuel, which, on the presumption that peat possesses

half the heating power of coal, is equivalent to 4 thousand million tons of

coal, or enough fuel to last for centuries. With the exception of Russia,

there is no country in Europe having such a plentiful supply of peat as

Sweden, and scarcely any country has peat of such good quality.

Although peat can be used successfully as fuel for domestic purposes, various

industries such as ironworks, cellulose factories, glass and tile works, etc., its

use is very insignificant as compared with that of coal and wood, and is not

at all proportionate to the natural resources. This is owing to the fact that

the preparation of peat depends upon the weather and also to the fact that it

has not yet been possible to arrange for the production of peat fuel on a large

scale, and therefore there is a state of uncertainty regarding the quantity and

quality of the peat and also as to the cost of manufacture. The continuous rise

in wages enhances the cost of manufacture, so that, for example, the cost -of

manufactured peat in the last 12 years has risen from 5— 6 to 8-—9 kr. per

ton, at the same time as the price of coal in port has meanwhile increased from

14 to 20 kr. and upwards per ton; all of which circumstances have caused a

state of uncertainty in the peat industry, which can only be removed by an

invention by which peat can be manufactured on a large scale, irrespective of

weather and seasons. There are, however, good prospects for such an invention

(the wet carbonizing process).

Every form of fuel is judged according to its calorific power, which is discovered

by experimental burning or by calorimetric analysis. Such methods has

been employed by professor P. Klason and others, with the result that 1 ton of

ordinary coal is found to be equivalent to l'S tons of average machine peat,

2 tons of cut peat or 2 ■> tons of wood. The cost of freight is, naturally, a

matter of greater importance when the fuel is of low value than when it is of

high value, this being another disadvantage for peat.

Many attempts have been made to refine peat to a more valuable fuel in the

form of peat-coal, powdered peat, and peat briquettes. Peat-coal, which seemed

at first to promise well, has not become an article of great production, principally

owing to the meagre production of the raw material for its manufacture.

Powdered peat has attracted a little attention but has not as yet been

produced on a large scale. Endeavours have been made to manufacture such

powder, by air-drying the raw peat, taken out by hand or by excavator, till it

contains about 50 % of water, after which the product is dried artificially, until

the water is reduced to about 15 %, and can then be either ground to a fine

powder which can be used directly as fuel or burnt in a so-called powder-burning

apparatus, or it can be compressed, at a temperature of 90°—100° C. under a

pressure of as much as 2 000 atmospheres, into peat briquettes in the same

manner as in the manufacture of lignite. But up to the present time these

attempts have failed through want of raw material in sufficient quantities and

low enough in price. Thus the peat problem has not yet been solved. It has

been suggested that power stations should be located on the bogs, by which

means the quality of the peat would not be of such great consideration, and this

proposal has been adopted on a small scale, but the state of uncertainty in the

preparation of the peat has made itself felt even here.

In addition to peat fuel there is an enormous supply in Sweden of white

moss, from which moss Utter is prepared, both for home consumption and

export; during the last few years this material has become of increasing economic

importance in farming as a manure absorbant and also as an addition to

the manure. The enormous sums which have been lost in ammonia from dungyards

by its evaporation into the air can now be saved; and the employment

of moss litter increases yearly. It is also useful as a preserving element in

fruit packing etc., as packing for double floorings, and for other purposes, among

others for town cleaning purposes, as a disinfectant for closets, etc.

In 1912, Sweden possessed 32 peat manufactories, apart from those which

manufacture for domestic use; these latter do not make statistical returns, although

they actually produce greater quantities than the regular manufactories.

The 32 above-mentioned manufactories employed 892 hands and produced 41 924

tons of peat, with a value of 407 400 kronor. In the same year there were

125 moss litter manufactories, employing 1 972 hands and producing 192 790

tons, with a value of 2 767 000 kronor. The export of moss litter in the same

year was 7 276 tons, and in 1913, including 3 100 tons of powdered peat, the

export was 7 135 .tons.

In 1902 the Riksdag made a grant of 1 ‘5 million kronor as a so-called peat

loan fund, which was gradually increased to 3‘6 million kronor owing to the

many applications for grants. Advances are made out of this fund to approved

factories up to */s of the value of the manufactory against good security,

which must be approved by the Exchequer. The interest is 4 / , and the

amortization of the loan, , at the rate of 10 % of the total sum, need not

begin until the fourth year after the making of the grant. The State also affords

financial assistance in other ways for the solving of the peat problem. In order

to assist the peat industry with scientific aid the State has appointed two peat

engineers with three assistants. In Emmaljunga in Skane, there is a peat school,

maintained by the State, in which instruction is given in the preparation of

peat for such -as wish to fit themselves for the positions of managers or fore

men of peat manufactories.

Charcoal.

The Swedish statistics of industry include in the group now under consideration

also the manufacture of charcoal; in 1912 there was no less than 23 009 569

hectoliters produced, valued at 12 762 000 kronor. The total number of factories

producing it was stated to be 407, employing 6 639 hands. The greatest

output was in Kopparberg Lan, its value being 2'6 million kronor; then came

the Lans of Gavleborg, Örebro and Vasternorrland, each with an output valued

resp. at 2’s, 2 -o and 1 ’7 million kronor. - • The production of charcoal in the

whole kingdom is greater than what is represented by the above figures, owing

to the requirements of the ironworks being supplied from sources from which

no returns are obtainable. Thus during 1912 the ironworks alone consumed

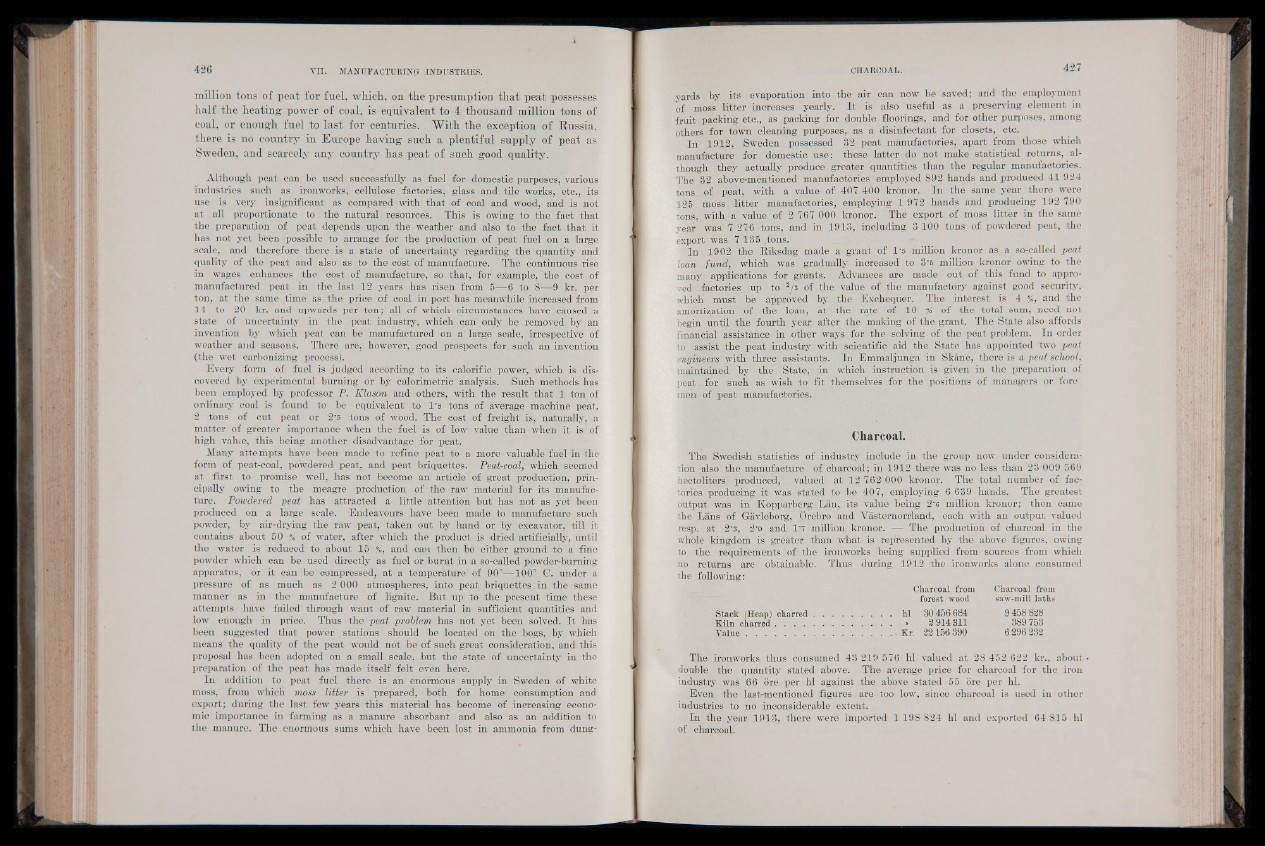

the following:

Charcoal from Charcoal from

forest wood saw-mill laths

Stack (Heap) charred hi 30 456 684 9 458 828

Kiln charred > 2 914 311 389 753

T a ln e .............................................................- Kr. 22 156 390 6 296 232

The ironworks thus consumed 43 219 576 hi valued at 28 452 622 kr., about-

double the quantity stated above. The average price for charcoal for the iron

industry was 66 ore per hi against the above stated 55 ore per hi.

Even the last-mentioned figures are too low, since charcoal is used in other

industries to no inconsiderable extent.

In the year 1913, there were imported 1 198 824 hi and exported 64 815 hi

of charcoal.