and the home crops have actually increased, it is manifest that the milling industry

has enlarged its scope considerably, and since, a s . already mentioned,- the

large factory mills driven by machinery have been gradually ousting the small

mills of former days, the output of the big steam mills-must evidently have

increased still more.

Margarine Industry.

The raw material out of which margarine was originally made was simply

fresh, unclarified tallow, obtained from homed cattle. This tallow is melted in

water at a temperature of about 50°— 60° 0 ., So as to form what is called “premier

jus”, which is then allowed to solidify at about 30° 0 ., after which it is

placed in cotton cloths and exposed to high pressure, whereupon a fluid portion,

called oleo-margarine, is obtained, together with a solid mass called pressed-tallow.

The oleo-margarine is then mixed with milk and churned, and afterwards manipulated

like ordinary butter, the product obtained being margarine. Oleo-margarine

alone, however, is, in general, too hard to give a fully satisfactory substitute

for butter, so that, before the process of churning, pure vegetable oils, such as

cotton-oil, sesam oil or pea-nut oil are added, these substances also contributing to

make the margarine cheaper. In accordance with a Royal Regulation of October

13, 1905, margarine, in order that it may be easily distinguished chemically

from butter, must contain at least 10 % of sesam oil “of all the fat and vegetable

oils, sesam oil therein included, employed in the manufacture”. In the superior

kinds of margarine, we find among these ingredients the best lard, so-called

neutral lard, together with natural (ordinary) butter, in considerable quantities. During

the last few years, considerable progress has been made in the margarine industry,

in consequence of the fact that, after efforts made during the preceding 25

years, it was at length found possible to clarify cocoa-nut oil and palm-lcernel oil so

that they remain fresh and of agreeable taste, and can thus be employed in

the manufacture of margarine. In such vegetable margarine (as it is called, in

order to distinguish it from animal-margarine with oleo-margarine and lard as the

principal raw ingredients), there exists no oleo-margarine, but only some of the

above-mentioned purified oils, together with the vegetable oils also mentioned

above. Vegetable margarine has a purer taste than the animal product, and is therefore

better suited for direct consumption, while, on the other hand, the margarine

prepared from animal ingredients is better for baking and cooking in general.

Since the beginning of 1910, vegetable margarine has supplanted the animal product,

so that the greatest part of the margarine consumed now consists of

vegetable margarine. This is the result, not only of the better taste in the case

of the vegetable margarine, but also its lower price which is about 2/s ° f that of

the animal margarine of the same quality; at the same time, the price of cocoa-

nut oil and palm-kemel oil has, consequently, risen, and nowadays these oils are

for the most part employed for the manufacture of margarine, instead of being

devoted to the manufacture of soap as they formerly were. I f the selling-price

of the better class of animal margarine is about 2/ 3 of that of ordinary butter,

that of vegetable margarine is not more than about half of the latter, so that

vegetable margarine forms a very good and cheap nutriment for the masses.

The manufacture of margarine was first begun in France in 1869 by Mege-

Mouries. In Sweden the first margarine factory was built in 1881, at Halsing-

borg, and in 1912 the country possessed 10 margarine-factories.employing 585

workmen. The consumption of margarine in 1912 was about 23 million kg,

corresponding to 4'i kg per head of the population per annum while, in Denmark,

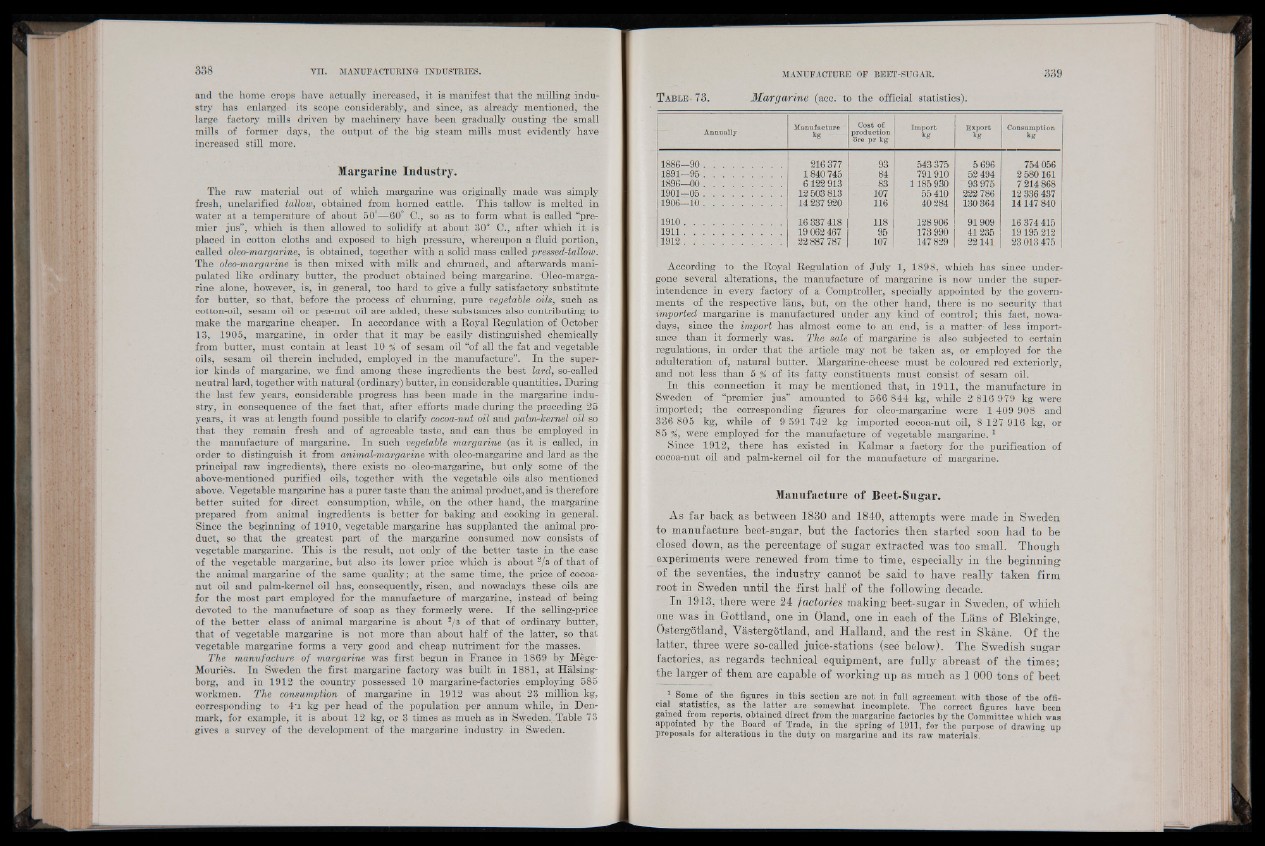

for example, it is about 12 kg, or 3 times as much as in Sweden. Table 73

gives a survey of the development of the margarine industry, in Sweden.

T a b l e - 73. M a r g a r in e (ace. to the official sta tis tic s ).

Annually Manufacture

kg -

Cost of

production

ore pr kg

Import

kg

Export

kg

Consumption

kg

1886—90 ................................ 216 377 93 543 375 5 696 754 056

1891—95 ................................ 1840 745 84 791 910 52 494 2580161

1896—00 ................................ 6 122 913 83 1185 930 93 975 7 214 868

1901—05 ................................ 12 503 813 107 55 410 222 786 12 336 437

1906—10 ................................ 14 237 920 116 40 284 130 364 14147 840

1910........................................ 16 337 418 118 128 906 91909 16 374 415

1911........................................ 19 062 467 95 173 990 41235 19 195 212

1912 ■ ................................ 22 887 787 107 147 829 22141 23 013 475

According to the Royal Regulation of July 1, 1898, which has since undergone

several alterations, the manufacture of margarine is now under the superintendence

in every factory of a Comptroller, specially appointed by the governments

of the respective Ians, but, on the other hand, there is no security that

imported margarine is manufactured under any kind of control; this fact, nowadays,

since the import has almost come to an end, is a matter- of less importance

than it formerly was. The sale of margarine is also subjected to certain

regulations, in order that the article may not be taken as, or employed for the

adulteration of, natural butter. Margarine-cheese must be coloured red exteriorly,

and not less than 5 % of its fatty constituents must consist of sesam oil.

In this connection it may be mentioned that, in 1911, the manufacture in

Sweden of “premier jus” amounted to 566 844 kg, while 2 816 979 kg were

imported; the corresponding figures for oleo-margarine were 1 409 908 and

336 805 kg, while of 9 591 742 kg imported cocoa-nut oil, 8 127 916 kg, or

85 %, were employed for the manufacture of vegetable margarine. 1

Since 1912, there, has existed in Kalmar a factory for the purification of

cocoa-nut oil and palm-kernel oil for the manufacture of margarine.

Manufacture of Beet-Sugar.

As far back as between 1830 and 1840, attempts were made in Sweden

to manufacture beet-sugar, but the factories then started soon had to be

closed down, as the percentage of sugar extracted was too small. Though

experiments were renewed from time to time, especially in the beginning

of the seventies, the industry cannot be said to have really taken firm

root in Sweden until the first half of the following decade.

In 1913, there were 24 factories making beet-sugar in Sweden, of which

one was in G-ottland, one in Oland, one in each of the Lans of Blekinge,

Ostergotland, Vastergotland, and Halland, and the rest in Skane. Of the

latter, three were so-called juice-stations (see below). The Swedish sugar

factories, as regards technical equipment, are fully abreast of the times;

the larger of them are capable of working up as much as 1 0 0 0 tons of beet

1 Some of the figures in this section are not in fnll agreement with those of the offi-

cial statistics, as the latter are somewhat incomplete. The correct figures have been

gained from reports, obtained direct from the margarine factories by the Committee which was

appointed by the Board of Trade, in the spring of 1911, for the purpose of drawing up

proposals for alterations in the duty on margarine and its raw materials.