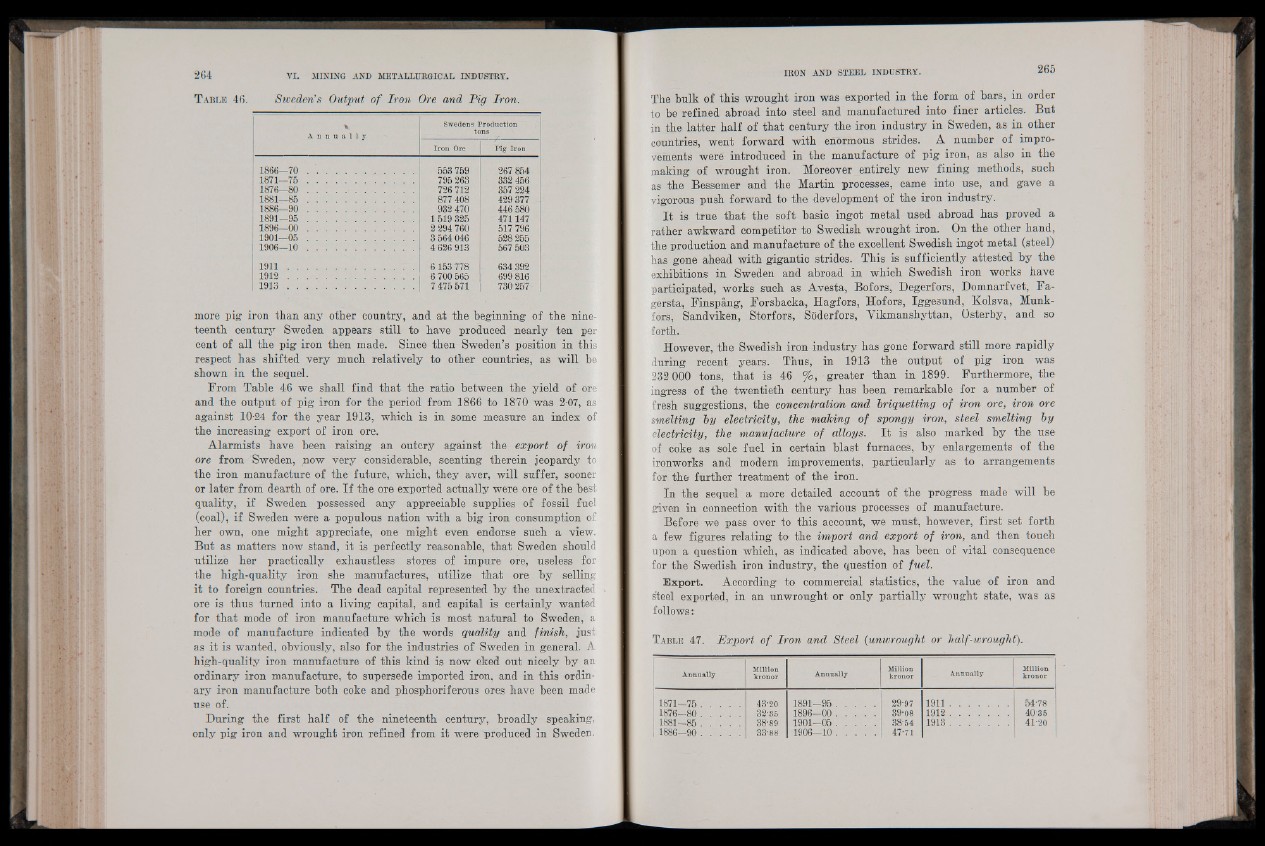

T able 46. Sweden's Output of Iron Ore and Pig Iron.

X

A n n u a l l y

Swedens ;

tc

Iron Ore

Production

ns

Pig Iron

1866—70 ............................................ 553 759 267 854

1871—75 ............................................ 795 263 332 456

1876—80 ............................................ 726 712 357 224

1881—85 ............................................ 877 408 429 377

1886—90 ........................................... 932 470 446 580

1891—95 ........................................... 1519325 471147

1896—00 ........................................... 2 294 760 517 796

1901—05 ............................................ 3 564 046 528 255

1906-10 ............................................ 4 626 913 567 503

1 9 1 1 .................................................... 6 153 778 634 392

1 9 1 2 .................................................... 6 700 565 699 816

1 9 1 3 .................................................... 7 475 571 730 257

more pig iron than any other country, and at the beginning of the nineteenth

century Sweden appears still to have produced nearly ten per

cent of all the pig iron then made. Since then Sweden’s position in this

respect has shifted very much relatively to other countries, as will he

shown in the sequel.

From Table 46 we shall find that the ratio between the yield of ore

and the output of pig iron for the period from 1866 to 1870 was 2-07, as

against 10-24 for the year 1913, which is in some measure an index of

the increasing export of iron ore.

Alarmists have been raising an outcry against the export of iron

ore from Sweden, now very considerable, scenting therein jeopardy to

the iron manufacture of the future, which, they aver, will suffer, sooner

or later from dearth of ore. I f the ore exported actually were ore of the best

quality, if Sweden possessed any appreciable supplies of fossil fuel

(coal), if Sweden were a populous nation with a big iron consumption of

her own, one might appreciate, one might even endorse such a view.

But as matters now stand, it is perfectly reasonable, that Sweden should

utilize her practically exhaustless stores of impure ore, useless for

the high-quality iron she manufactures, utilize that ore by selling

it to foreign countries. The dead capital represented by the unextracted

ore is thus turned into a living capital, and capital is certainly wanted

for that mode of iron manufacture which is most natural to Sweden, a

mode of manufacture indicated by the words quality and finish, just

as it is wanted, obviously, also for the industries of Sweden in general. A

high-quality iron manufacture of this kind is now eked out nicely by an

ordinary iron manufacture, to supersede imported iron, and in this ordinary

iron manufacture both coke and phosphoriferous ores have been made

use of.

During the first half of the nineteenth century, broadly speaking,

only pig iron and wrought iron refined from it were produced in Sweden.

The bulk of this wrought iron was exported in the form of bars, in order

to be refined abroad into steel and manufactured into finer articles. But

in the latter half of that century the iron industry in Sweden, as in other

countries, went forward with enormous strides. A number of improvements

were introduced in the manufacture of pig iron, as also in the

making- of wrought iron. Moreover entirely new fining methods, such

as the Bessemer and the Martin processes, came into use, and gave a

vigorous push forward to the development of the iron industry.

It is true that the soft basic ingot metal used abroad has proved a

rather awkward competitor to Swedish wrought iron. On the other hand,

the production and manufacture of the excellent Swedish ingot metal (steel)

has gone ahead with gigantic strides. This is sufficiently attested by the

exhibitions in Sweden and abroad in which Swedish iron works have

participated, works such as Avesta, Bofors, Degerfors, Domnarfvet, Fa-

gersta, Finspang, Forsbacka, Hagfors, Hofors, Iggesund, Kolsva, Munk-

fors, Sandviken, Storfors, Soderfors, Vikmanshyttan, Osterby, and so

forth.

However, the Swedish iron industry has gone forward still more rapidly

during recent, years. Thus, in 1913 the output of pig iron was

232 000 tons, that is 46 %, greater than in 1899. Furthermore, the

ingress of the twentieth century has been remarkable for a number of

fresh suggestions, the concentration and briquetting of iron ore, iron ore

smelting by electricity, the making of spongy iron, steel smelting by

electricity, the manufacture of alloys. It is also marked by the use

of coke as sole fuel in certain blast furnaces, by enlargements of the

ironworks and modern improvements, particularly as to arrangements

for the further treatment of the iron.

In the sequel a more detailed account of the progress made will be

given in connection with the various processes of manufacture.

Before we pass over to this account, we must, however, first set forth

a few figures relating to the import and export of iron, and then touch

upon a question which, as indicated above, has been of vital consequence

for the Swedish iron industry, the question of fuel.

Export. According to commercial statistics, the value of iron and

steel exported, in an unwrought or only partially wrought state, was as

follows:

T a b le 47. Export of Iron and Steel (unwrought or half-wrought).

Annually

kronor Annually Million

Million

kronor Annually Million

kronor

1871-75 ................ 43-20 1891—95 ................ 29-97 1911........................ 54-78

1876—80 . . . . . 32-35 1896—00 ................ 39-08 1912 . . . . . . . 40-35

1881—85 ................ 38-89 1901—05 ................ 38-54 1913........................ 41-20

1886-90 ................ 33-88 1906—10 ................ 47-71