the combustion and obtaining from them a number of valuable products (tar,

oil of terpentine, wood spirit, and acetic acid). Presumably they will come into

more extensive use in the future. Another reason why the kilns are resorted

to is the difficulty of obtaining a sufficient number of skilled charcoal-burners

for the heaps.

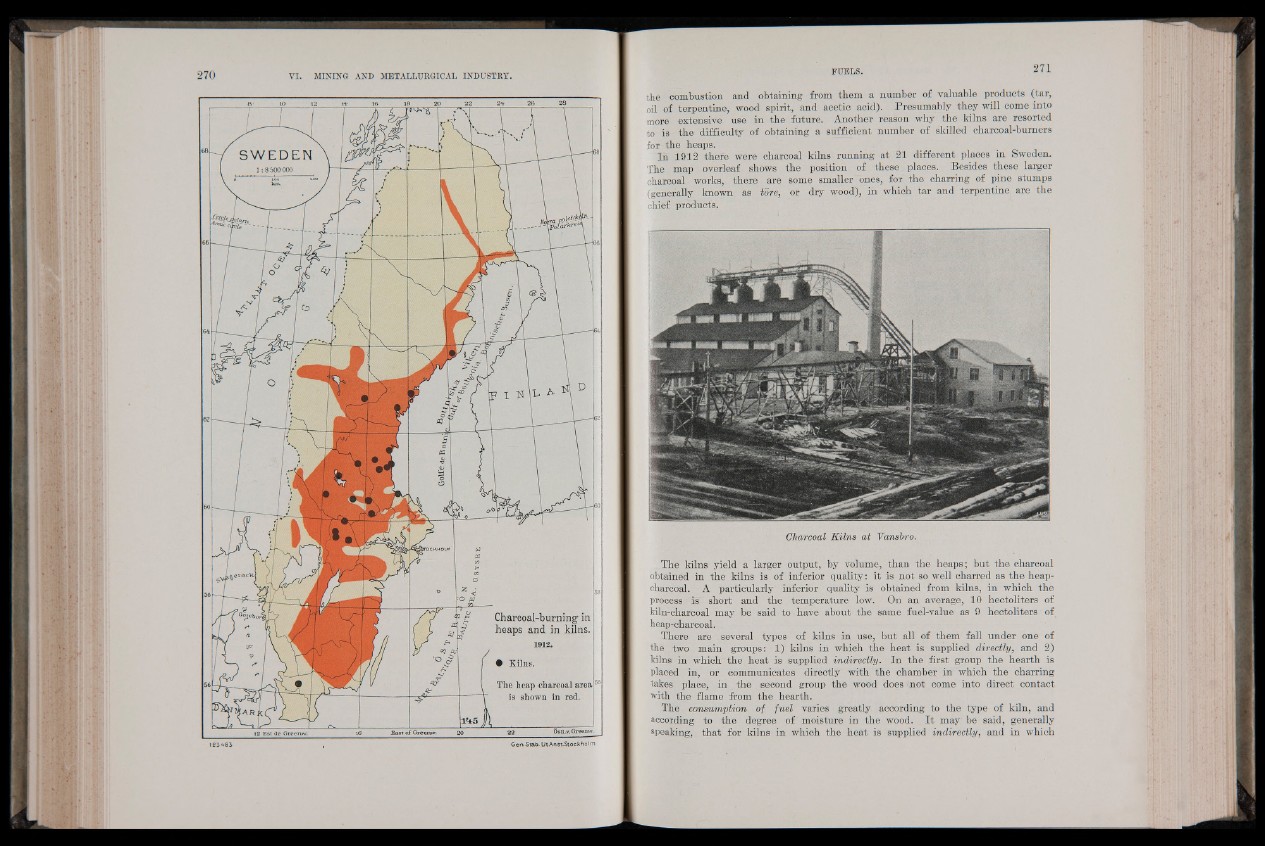

In 1912 there were charcoal kilns running at 21 different places in Sweden.

The map overleaf shows the position of these places. Besides these larger

charcoal works, there. are some smaller ones, for the charring of pine stumps

(generally known as fore, or dry wood), in which tar and terpentine, are the

chief products,

Charcoal Kilns at Vansbro.

The kilns yield a larger output, by volume, than the heaps; but the charcoal

obtained in the kilns is of inferior quality: it is not so well charred as the heap-

charcoal. A particularly inferior quality is obtained from kilns, in which the

process is" short and the temperature low. On an average, 10 hectoliters of

kiln-chareoal may be said to have about the same fuel-value as 9 hectoliters of

heap-charcoal.

There are several types of kilns in use, but all of them fall under one of

the two main groups: 1) kilns in which the heat is supplied directly, and 2)

kilns in which the heat is supplied indirectly. In the first group the hearth is

placed in, or communicates directly with the chamber in which the charring

takes place, in the second group the wood does »not come into direct contact

with the flame from the hearth.

The consumption of fuel varies greatly according to the type of kiln, and

according to the degree of moisture in the wood. It may be said, generally

speaking, that for kilns in which the heat is supplied indirectly, and in which