The Manufacture of Pig Iron.

Pig-iron was first manufactured in Sweden not later than the fifteenth

century: the date cannot be determined more precisely. The manufacture

of pig-iron gradually developed out of the process called blaster-

smide or the blast forging, the product of which was wrought iron.

Statistics of pig-iron manufacture are also unsatisfactory - for the earlier

periods: they can scarcely be said to be reliable before they get down to the

nineteenth century.

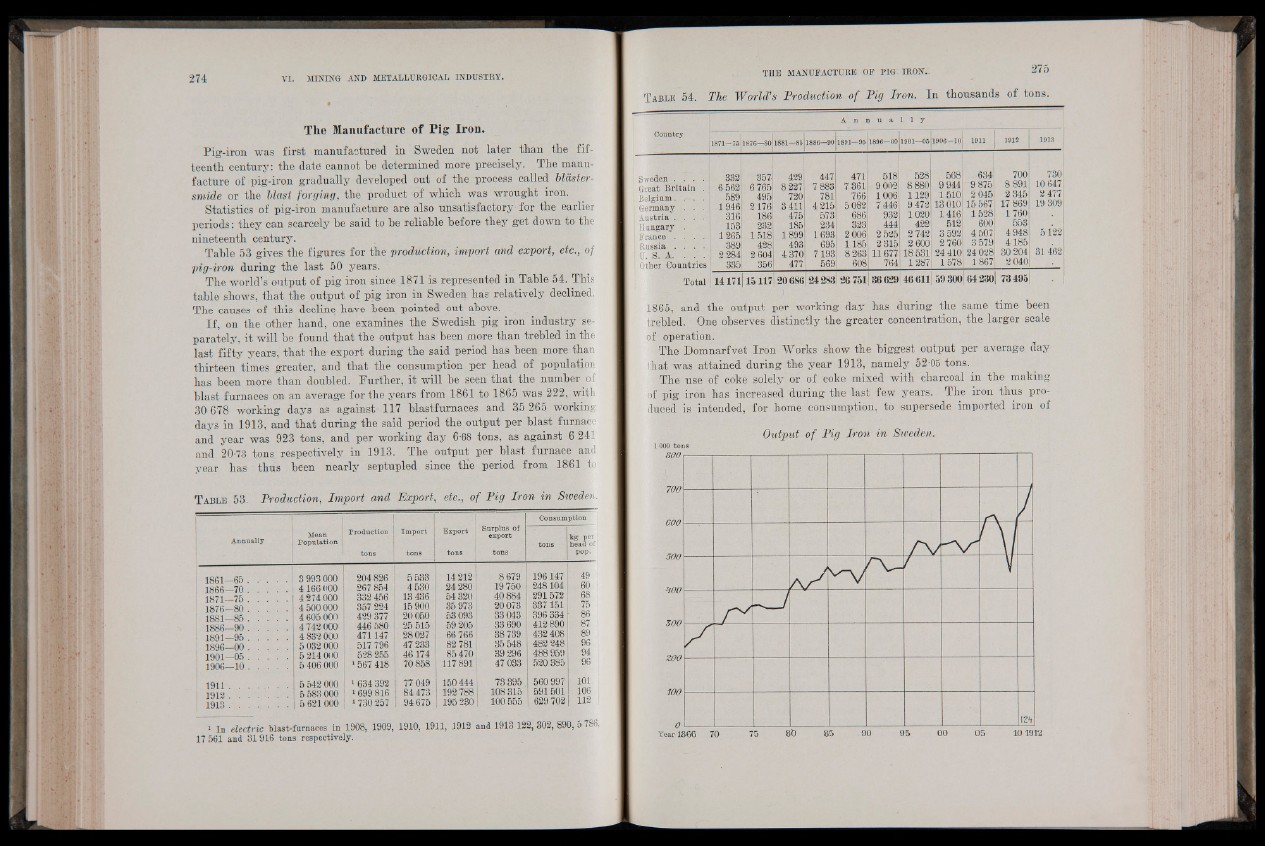

Table 53 gives the figures for the production, import and export, etc., of

pig-iron during the last 50 years.

The world’s output of pig iron since 1871 is represented in Table 54. This

table shows, that the output of pig iron in Sweden has relatively declined.

The causes of this decline have been pointed out above.

If, on the other hand, one examines the Swedish pig iron industry separately,

it will be found that the output has been more than trebled in the

last fifty years, that the-export during the said period has been more than

thirteen times greater, and that the consumption per head of population

has been more than doubled. Further, it will be seen that the number of

blast furnaces on an average for the years from 1861 to 1865 was 222, with

30 678 working days as against 117 blast-furnaces and 35 265 working

days in 1913, and that during the said period the output per blast furnace

and year was 923 tons, and per working day 6-68 tons, as against 6 241

and 20-73 tons respectively in 1913. The output per blast furnace and

year has thus been nearly septupled since tlfe period from 1861 ito

T able 53. Production, Import and Export, etc., of Pig Iron in Sweden.

Consumption

Annually

Mean

Population

Production Import Export Snrplus of

export

tons

kg per

head of

tons tons tons tons pop.

1861—65 ................

1866—70 ................

1871—75 ................

1876-80 ................

1881—85 ................

1886 90 ................

1891—95 ................

1896—00 ................

1901 05 ................

1906—10 ................

3 993 000

4166 000

4 274 000

4 500 000

4 605 000

4 742 000

4 832 000

5 032 000

5 214 01)0

5 406 000

204 826

267 854

332 456

357 224

429 377

446 580

471147

517 796

528 255

§ 567 418

5 533

4 530

13 436

15 900

20 050

25 515

28 027

47 233

46174

70 858

14212

24 280

54320

35 973

53 093

59 205

66 766

82 781

85 470

117 891

8 679

19750

40 884

20 073

33 043

33 690

38739

35 548

39 296

47 033

196147

248 104

291572

337151

396 334

412 890

432 408

482 248

488 959

520 385

Kv49

; 60

68

75

1 86

■ I

89

■ 96

94

96

191 1 ....................

191 2 ....................

191 3 ....................

5 542 000

5583 000

5 621 000

1 634 392

1 699 816

1730 257

77 049

84 473

94 675

150 444

192 788

195 230

73 395

108 315

100 555

560 997

591501

629 702

101

106

112

‘ In electric blast-furnaces in 1908, 1909, 1910, 1911, 1912 a n d 1 9 1 3 1 2 2 , 302, 890, 5 786,

17 561 and 31916 tons respectively.

THE MANUFACTURE OF PIG. IRON- 275

T a b le 54. The World’s Production of Pig Iron. In thousands of tons.

Country

A n u a i i y

1871—75 1876—80 1881—86 1886—90 1891—95 1896—00 1901—06 1906-10 1911 1 1912 1913

332 357- 429 447 471 518 528 568 634 700 730

6 562 6 765 8227 7 883 7 361 9 002 8 880 9 944 9 875 8 891 10 647

589 495 720 781 766 1006 1129 1510 2 045 2 345 2 477

J. 946 2176 3 411 4 215 5 082 7446 9 47-2 13 010 15567 17 869 19 309

316 1.86 475 573 686 932 1020 1416 1528 1 760

153 232 185 234 323 444 422 512 600 553

1265 1518 1899 1'693 2 006 2 525 2 742 3 592 4 507 4 948 5122

389 428 493 695 1185 2 315 2 600 2 760 3 579 4185

Ü. -S. A. . . . 2 284 2 604 4370 7193 8263 11677 18 531 24410 24 028 30 204 31 462

Other Countries 335 356 4771 569 608 764| 1287 1578 1867 2 040

Total 14 171 15117 20 686 24 283 26 751 36 629 46 611 59 300 64 230| 73495

1865, and the output per working day has during the same time been

trebled. One observes distinctly the greater concentration, the larger scale

of operation.

The Domnarfvet Iron Works show the biggest output per average day

that was attained during the year 1913, namely 52-05 tons.

The use of coke solely or of coke mixed with charcoal in the making

of pig iron has increased during the last few years. The iron thus produced

is intended, for home consumption, to supersede imported iron of

Output of Pig Iron in Sweden.

1 000 tons