houses and other buildings either electric lamps or Lux lamps are employed.

At the open cut works in the export fields electric incandescent

lamps are burnt during the dark hours.

Ore-Treatment. In most of the iron mines the separation of the valuable

minerals from the valueless material is carried out simply by hand-

sorting and hand-picking in rock-houses erected in the immediate neighbourhood

of the shaft-head. The small ores (syltan) is afterwards subjected

to washing and picking by hand.

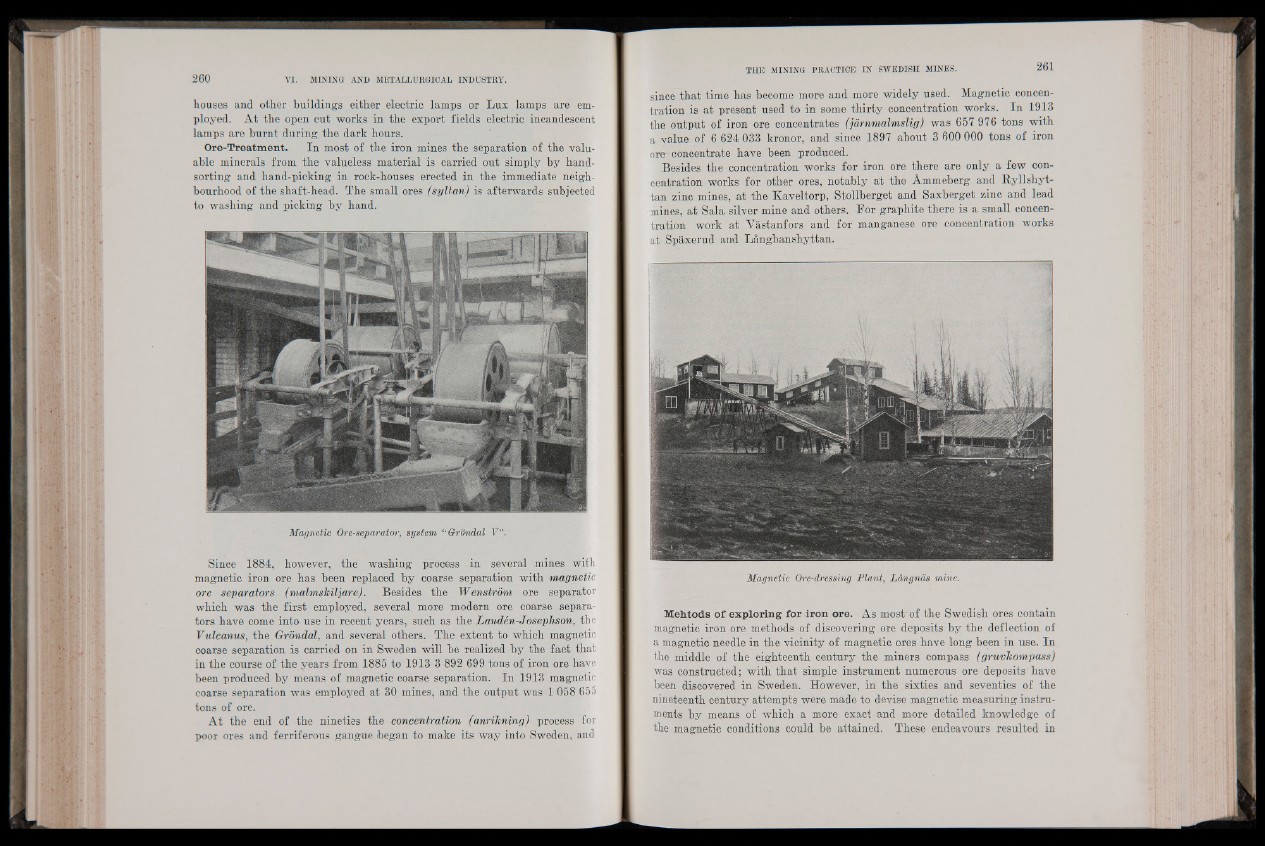

Magnetic Ore-separator, system “Griindal V".

Since 1884, however, the washing process in several mines with

magnetic iron ore has been replaced by coarse separation with magnetic

ore separators (malmskiljare). Besides the Wenstrom ore separator

which was the first employed, several more modern ore coarse separators

have come into use in recent years, such as the Landen-Josephson, the

Vulcanus, the Grondal, and several others. The extent to which magnetic

coarse separation is carried on in Sweden will be realized by the fact that

in the course of the years from 1885 to 1913 3 892 699 tons of iron ore have

been produced by means of magnetic coarse separation. In 1913 magnetic

coarse separation was employed at 30 mines, and the output was 1 058 655

tons of ore.

At the end of the nineties the concentration (anrikning) process for

poor ores and ferriferous gangue began to make its way into Sweden, and

since that time has become more and more widely used. Magnetic concentration

is at present used to in some thirty concentration works. In 1913

the output of iron ore concentrates (jarnmalmslig) was 657 976 tons with

a value of 6 624 033 kronor, and since 1897 about 3 600 000 tons of iron

ore concentrate have been produced.

Besides the concentration works for iron ore there are only a few concentration

works for other ores, notably at the Ammeberg and Ryllshyt-

tan zinc mines, at the Kaveltorp, Stollberget and Saxberget zinc and lead

mines, at Sala silver mine and others. For graphite there is a small concentration

work at Yastanfors and for manganese ore concentration works

at Spaxerud and Langbanshyttan.

Magnetic Ore-dressing Plant, Làngnâs mine. "

Mehtods o f exploring for iron ore. As most'of the Swedish ores contain

magnetic iron ore methods of discovering ore deposits by the deflection of

a magnetic needle in the vicinity of magnetic ores have long been in use. In

the middle of the eighteenth century the miners compass (gruvlcompass)

was constructed; with that simple instrument numerous ore deposits have

been discovered in Sweden. However, in the sixties and seventies of the

nineteenth century attempts were made to devise magnetic measuring instruments

by means of which a more exact and more detailed knowledge of

the magnetic conditions could be attained. These endeavours resulted in