Swedish Curtain Manufactory) in Gothenburg, with a branch in Christiania,

since the abrogation of the commercial treaty between Sweden and

Norway (“mellanrikslagen”), manufactures so-called thread curtains or

network textiles, white as well as coloured, which have already secured a

firm footing on the market and are, as far as quality is concerned, fully

worthy of comparison with the best obtained from abroad. These goods

are exported as well. There is a Norwegian competitor in the trade

at Bergen, who has had a branch-works at Svartvik, outside Stockholm,

since the abrogation of the commercial treaty between Sweden and Norway.

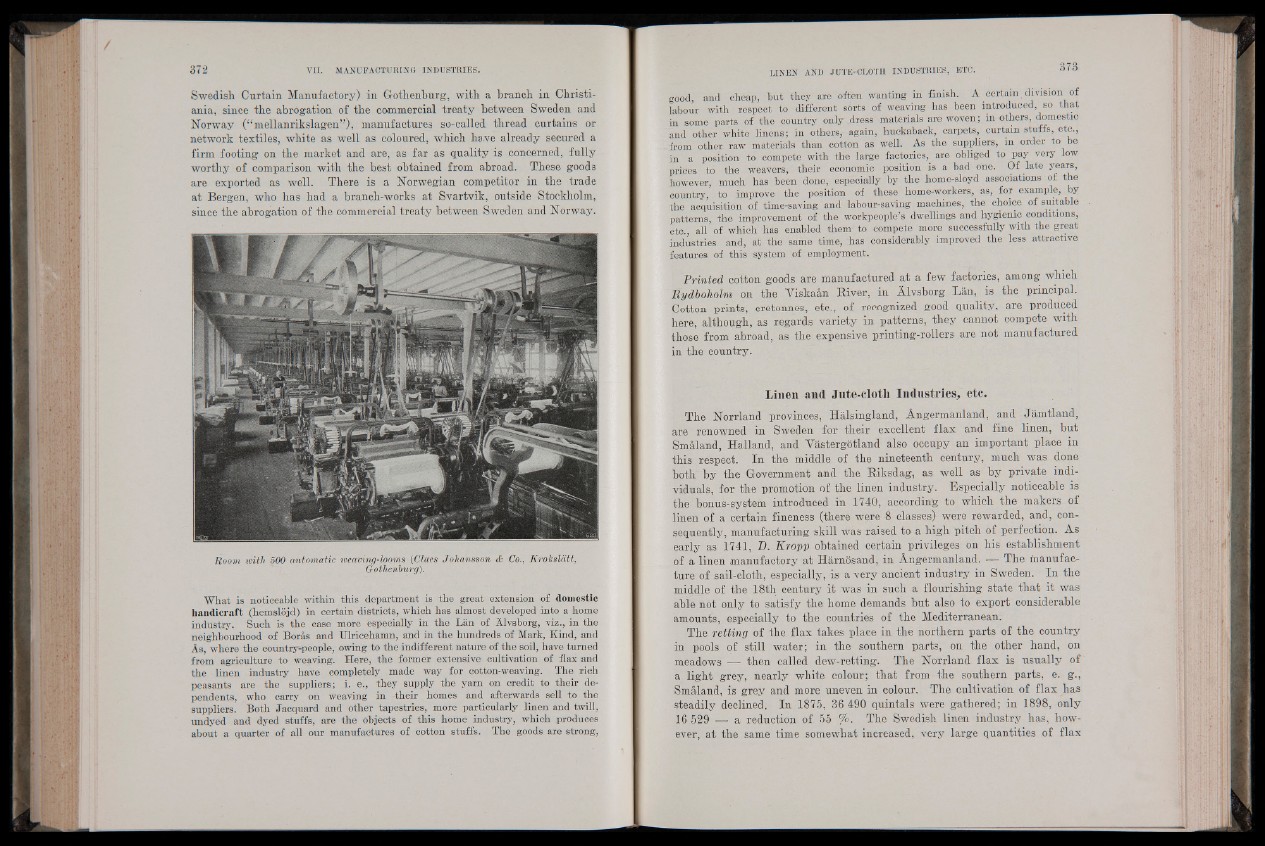

Room ioith 500 automatic iceaving-looms (Claes Johansson & Co., Krokslàtt,

Gothenburg).

What is noticeable within this department is the great extension of domestic

handicraft (hemslojd) in certain districts, which has almost developed into a home

industry. Such is the case more especially in the Lan of Alvsborg, viz., in the

neighbourhood of Boras and Ulricehamn, and in the hundreds of Mark, Kind, and

As, where the country-people, owing to the indifferent nature of the soil, have turned

from agriculture to weaving. Here, the former extensive cultivation of flax and

the linen industry have completely made way for cotton-weaving. The rich

peasants are the suppliers; i. e., they supply the yam on credit to their dependents,

who carry on weaving in their homes and afterwards sell to the

suppliers. Both Jacquard and other tapestries, more particularly linen and twill,

undyed and dyed stuffs, are the objects of this home industry, which produces

about a quarter of all our manufactures of cotton stuffs. The goods are strong,

good, and cheap, but they are often wanting in finish. A certain division of

labour with respect to different sbrts of weaving has been introduced, so that

in some parts of the country only dress materials are woven; in others, domestic

and other white linens; in othersj-again, huckaback, carpets, curtain stuffs, etc.,

from other raw materials than cotton as well. As the suppliers, in order to be

in a position to compete with the large factories,_ are obliged to pay very low

prices to the weavers, their economic position is a bad one. Of late years,

however, much has been done, especially by the home-sloyd associations of the

country, to improve the position of these home-workers, as, for example, by

the acquisition of time-saving and labour-saving machines, the choice of suitable

patterns, the improvement of the workpeople’s dwellings and hygienic conditions,

etc., all of which has enabled them1 to compete more successfully with the great

industries and, at the same time, has considerably improved the less attractive

features of this system of employment.

Printed cotton goods are manufactured at a few factories, among which

Rydboholm on the Viskaan River, in Alvsborg Lan, is the principal.

Cotton prints, cretonnes, etc., of recognized good quality, are produced

here, although, as regards variety in patterns, they cannot compete with

those from abroad, as the expensive printing-rollers are not manufactured

in the country.

Linen and Jute-cloth Industries, etc.

The Norrland provinces, Halsingland, Angermanland, and Jamtland,

are renowned in Sweden for their excellent flax and fine linen, but

Smaland, Halland, and Vastergotland also occupy an important place in

this respect. In the middle of the nineteenth century, much was done

both by the Government and the Riksdag, as well as by private individuals,

for the promotion of the linen industry. Especially noticeable is

the bonus-system introduced in 1740, according to which the makers of

linen of a certain fineness (there were 8 classes) were rewarded, and, consequently,

manufacturing skill was raised to a high pitch of perfection. As

early as 1741, D. Kropp obtained certain privileges on his establishment

of a linen manufactory at Harnosand, in Angermanland. —■ The manufacture

of sail-cloth, especially, is a very ancient industry in Sweden. In the

middle of the 18th century it was in such a flourishing state that it was

able not only to satisfy the home demands but also to export considerable

amounts, especially to the countries of the Mediterranean.

The retting of the flax takes place in the northern parts of the country

in pools of still water; in the southern parts, on the other hand, on

meadows — then called dew-retting. The Norrland flax is usually of

a light grey, nearly white colour; that from the southern parts, e. g.,

Smaland, is grey and more uneven in colour. The cultivation of flax has

steadily declined. In 1875, 36 490 quintals were gathered; in 1898, only

16 529 — a reduction of 55 %. The Swedish linen industry has, however,

at the same time somewhat increased, very large quantities of flax