bridge into the mill. One end of the log is then attached to a frame on wheels

(“log-carriage”), while the other end rests on a cylinder or roller near the

saw-blades. The latter are stretched in a strong swing-frame, which runs up

and down in the bearings of a pair of upright frames. The movement of the

swing-frame is produced by a rod secured to the lower edge of the frame,

whose other end is connected with a crank, which is caused to rotate by wheels.

By means of gearing connected with these, the log-carriage is led forward,

while the sawing is going on. The number of saw-blades in a frame depends

upon the size of the logs and the thickness of the boards to be sawn, so that,

the log is sawn up into boards at its first passage through the frame, unless

square-sawing is adopted, which is frequently the case with large logs; in this

case, the logs are first sawn on two outer sides before the sawing proper begins

in the next frame. On account of the evenness of Swedish timber, it has not

been found necessary to. make use of band-saws, the working up of the logs

being made almost everywhere by gang-saws, which, in its simplest form, is of

the kind described above; at large saw-mills with modern appliances, special,

machines are often used to perform the work more rapidly.

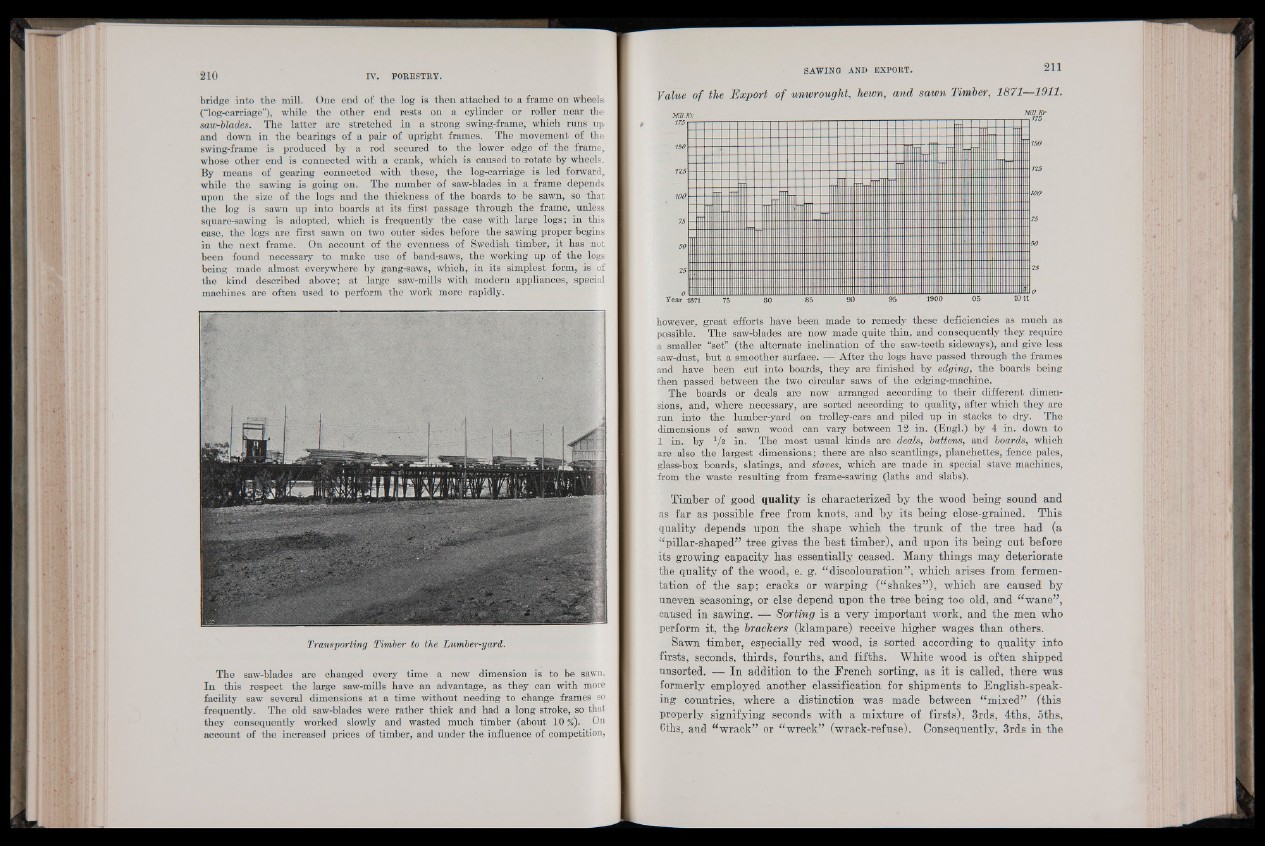

Transporting Timber to the Lumber-yard.

The saw-blades are changed every time a new dimension is to be sawn.

In this respect the large saw-mills have an advantage, as they can with more

facility saw several dimensions at a time without needing to change frames so

frequently. The old saw-blades were rather thick and had a long stroke, so that

they consequently worked slowly and wasted much timber (about 10 %)■ On

account of the increased prices of timber, and under the influence of competition,

SAWING AND EXPORT. 211

Value of the Export of unwrought, hewn, and sawn Timber, 1871—1911.

however, great efforts have been made to remedy these deficiencies as much as

possible. The saw-blades are now made quite thin, and consequently they require

a smaller “.set” (the alternate inclination of the saw-teeth sideways), and give less

saw-dust, but a smoother surface. — After the logs have passed through the frames

and have been cut into boards, they are finished by edging, the boards being

then passed between the two circular saws of the edging-machine.

The boards or deals are now arranged according to their different dimensions,

and, where necessary, are sorted according to quality, after which they are

rim into the lumber-yard on trolley-cars and piled up in stacks to dry. The

dimensions of sawn wood can vary between 12 in. (Engl.) by 4 in. down to

1 in. by 1/s in. The most usual kinds are deals, battens, and boards, which

are also the largest dimensions; there are also scantlings, planchettes, fence pales,

glass-box boards, slatings, and staves, which are made in special stave machines,

from thé waste resulting from frame-sawing (laths and slabs).

Timber of good quality is characterized by the wood being sound and

as far as possible free from knots, and by its being close-grained. This

quality depends upon the shape which the trunk of the tree had (a

“pillar-shaped” tree gives the best timber), and upon its being cut before

its growing capacity has essentially ceased. Many things may deteriorate

the quality of the wood, e. g. “ discolouration”, which arises from fermentation

of the sap; cracks or warping (“shakes”), which are caused by

uneven seasoning, or else depend upon the tree being too old, and “wane”,

caused in sawing. — Sorting is a very important work, and the men who

perform it, the brackers (klampare) receive higher wages than others.

Sawn timber, especially red wood, is sorted according to quality into

firsts, seconds, thirds, fourths, and fifths. White wood is often shipped

unsorted. —- In addition to the French sorting, as it is called, there was

formerly employed another classification for shipments to English-speaking

countries, where a distinction was made between “mixed” (this

properly signifying seconds with a mixture of firsts), 3rds, 4ths, 5ths,

6ths, and “wrack” or “wreck” (wrack-refuse). Consequently, 3rds in the