based on ammonium perchlorate, of Swedish make, named territe has come

into use alongside of gelatine dynamite.

Concerning the general effect of blasting in the Swedish ore mines the

amount of rock broken down varies on an average between 8 and 15 tons,

and, where circumstances are favourable, 20 to 25 tons per kilogram of

explosive, and between 2 and 3 up to 8 to 15 tons, and in the open-cuts in

the export fields between 1 0 and 2 0 tons per meter drilled.

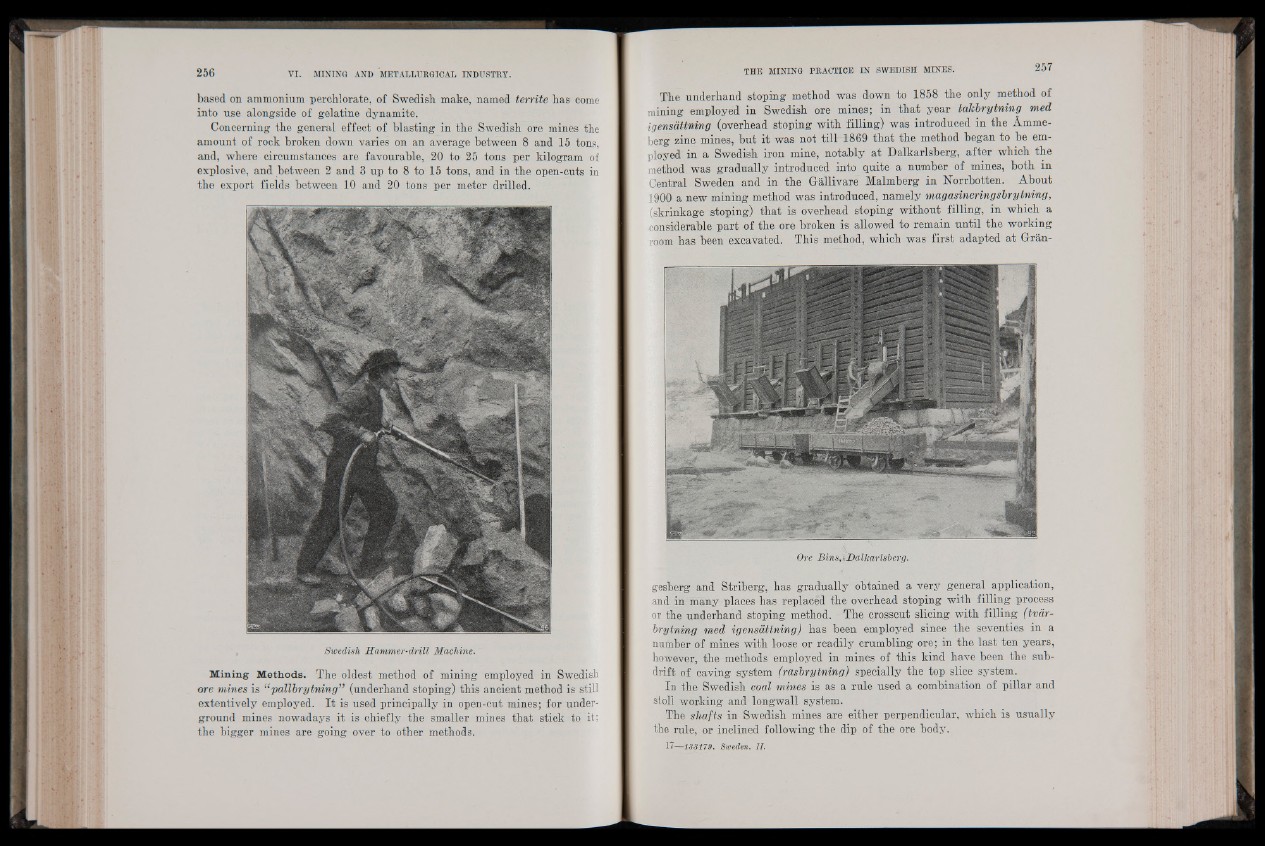

Swedish Hammer-drill Machine.

Mining Methods. The oldest method of mining employed in Swedish

ore mines is “pallbrytning” (underhand stoping) this ancient method is still

extentively employed. It is used principally in open-cut mines; for underground

mines nowadays it is chiefly the smaller mines that stick to it;

the bigger mines are going over to other methods.

The underhand stoping method was down to 1858 the only method of

mining employed in Swedish ore mines; in that year takbrytning med

igensattning (overhead stoping with filling) was introduced in the Amme-

berg zinc mines, but it was not till 1869 that the method began to be employed

in a Swedish iron mine, notably at Dalkarlsberg, after which the

method was gradually introduced into quite a number of mines, both in

Central Sweden and in the Gallivare Malmberg in Norrbotten. About

1900 a new mining method was introduced, namely magasineringsbrytning,

(shrinkage stoping) that is overhead stoping without filling, in which a

considerable part of the ore broken is allowed to remain until the working

room has been excavated. This method, which was first adapted at Gran-

Ore Bins,¿Dalkarlsberg.

gesberg and Striberg, has gradually obtained a very general application,

and in many places has replaced the overhead stoping with filling process

or the underhand stoping method. The crosscut slicing with filling (tvar-

brytning med igensattning) has been employed since the seventies in a

number of mines with loose or readily crumbling ore; in the last ten years,

however, the methods employed in mines of this kind have been the subdrift

of caving system (rasbrytning) specially the top slice system.

In the Swedish coal mines is as a rule used a combination of pillar and

stoll working and longwall system.

The shafts in Swedish mines are either perpendicular, which is usually

the rule, or inclined following the dip of the ore body.