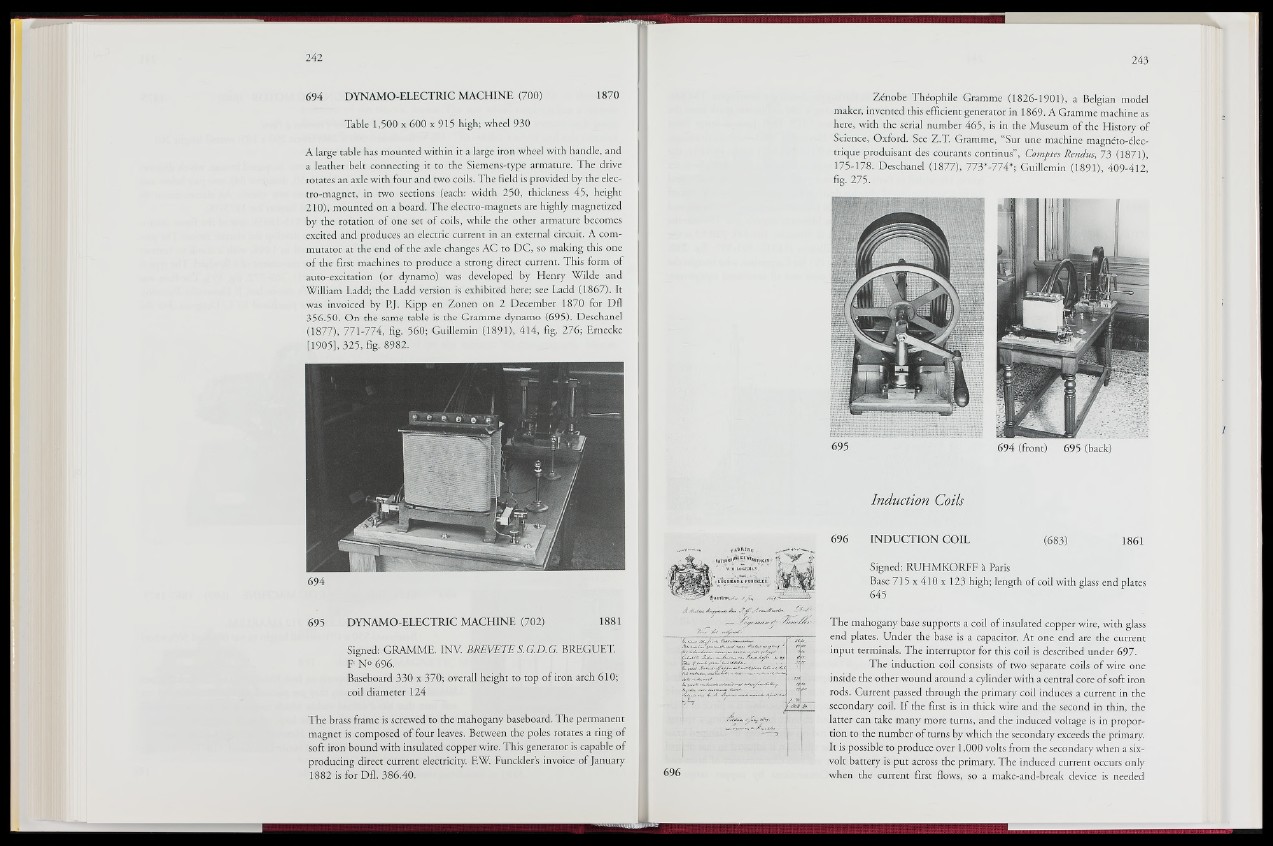

694 DYNAMO-ELECTRIC MACHINE (700) 1870

Table 1,500 x 600 x 915 high; wheel 930

A large table has mounted within it a large iron wheel with handle, and

a leather belt connecting it to the Siemens-type armature. The drive

rotates an axle with four and two coils. The field is provided by the electro

magnet, in two sections (each: width 250, thickness 45, height

210), mounted on a board. The electro-magnets are highly magnetized

by the rotation of one set of coils, while the other armature becomes

excited and produces an electric current in an external circuit. A commutator

at the end of the axle changes AC to DC, so making this one

of the first machines to produce a strong direct current. This form of

auto-excitation (or dynamo) was developed by Henry Wilde and

William Ladd; the Ladd version is exhibited here; see Ladd (1867). It

was invoiced by P.J. Kipp en Zonen on 2 December 1870 for Dfl

356.50. On the same table is the Gramme dynamo (695). Deschanel

(1877), 771-774, fig. 560; Guillemin (1891), 414, fig. 276; Ernecke

[1905], 325, fig. 8982.

694

695 DYNAMO-ELECTRIC MACHINE (702) 1881

Signed: GRAMME. INV. BREVETE S.G.D.G. BREGUETJ

P N° 696.

Baseboard 330 x 370; overall height to top of iron arch 610;

coil diameter 124

The brass frame is screwed to the mahogany baseboard. The permanent

magnet is composed of four leaves. Between the polls rotates a ring of

soft iron bound with insulated copper wire. This generator is capable of

producing direct current electricity. EW. Funckler s invoice of January

1882 is for Dfl. 386.40.

Zénobe Théophile Gramme (1826-1901), a Belgian model

maker, invented this efficient generator in 1869. A Gramme machine as

here, with the serial number 465, is in the Museum of the History of

Science, Oxford. See Z.T. Gramme, “Sur une machine magnéto-électrique

produisant des courants continus”, Comptes Rendus, 73 (1871),

175-178. Deschanel (18P#)r773*-774*; Guillemin (1891), 409-412,

fig. 275.

695 694 (front) 695 (back)

Induction Coils

696 INDUCTION COIL (683) 1861

696

Signed: RUHMKORFF á Paris

Base 715 x 410 x 123 high; length of coil with glass end plates

645

The mahogany: base supports a coil of insulated copper wire, with glass

end plates. Under the base is a capacitor. At one end are the current

input terminals. The interruptor for this coilws described under 697.

The induction coil consists of two separate coils of wire one

inside the other wound around a cylinder with a central core of soft iron

rods. Current passed through the primary coil induces a current in the

secondary coil. If the first is in thick wire and the second in thin, the

latter can take many more turns, and the induced voltage is in proportion

to the number of turns by which the secondary exceeds the primary.

It is possible to produce over 1,000 volts from the secondary when a six-

volt battery is put across the primary. The induced current occurs only

when the current first flows, so a make-and-break device is needed