a A

138 PRESSURE RECEIVERS 1792 (205, 205/a) Fig. i4ia, 141 b

By A. Watt, Amsterdam

a Overall height 610, height of glass cylinder 330, diameter 128. This pressure

receiver is composed of a thick-glass cylinder, with ground rims, held between a brass

base plate and a conical brass cap by three iron clamping bars. The cap is pressed in

place by a stout screw. Inside the receiver is a glass bt'aker holding a boxwood

board that supports two gauge tubes. These are glass tubes, closed at the top, with

boxwood scales tied to them. The scales are divided from 0 to 12 inches in twelfths.

The construction of this receiver is shown in the Verhandelingen (1798). It was used

with the air-pump made by Watt (Cat. 137) to liquify ammonia,

b Overall height 590, average diameter of cylinder 128. This receiver resembles that

described above. The glass cylinder, with ground rims is held between brass cones,

clamped in place by a steel framework and screw. There is a stopcock below for

attaching to an air-pump; it is supported on a mahogany base.

Van Marum (1798) 111-114, XIV.

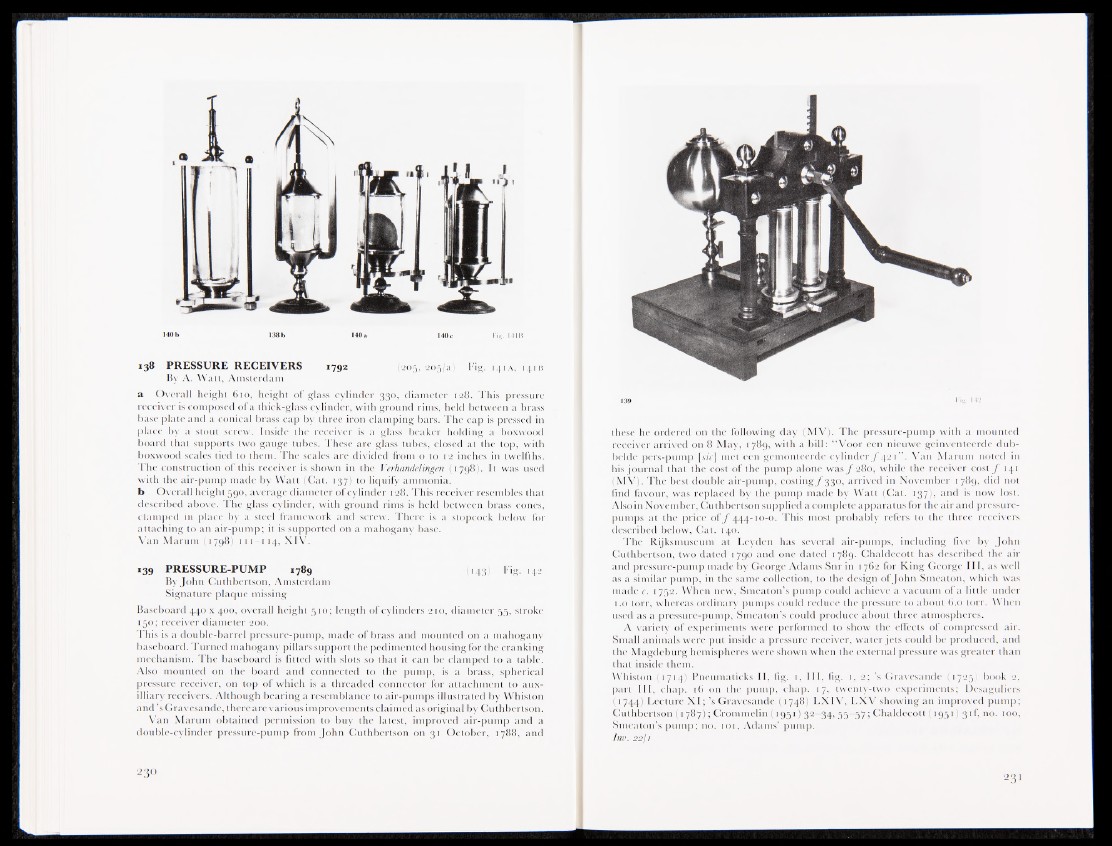

139 PRESSURE-PUMP 1789 (143) Fig. 142

By John Cuthbertson, Amsterdam

Signature plaque missing

Baseboard 440 x 400, overall height 510; length of cylinders 210, diameter 55, stroke

150; receiver diameter 200.

This is a double-barrel pressure-pump, made of brass and mounted on a mahogany

baseboard. Turned mahogany pillars support the pedimented housing for the cranking

mechanism. The baseboard is fitted with slots so that it can be clamped to a table.

Also mounted on the board and connected to the pump, is a brass, spherical

pressure receiver, on top of which is a threaded connector for attachmenSto aux-

illiary receivers. Although bearing a resemblance to air-pumps illustrated by Whiston

and’s Gravesande, there are various improvements claimed as original by Cuthbertson.

Van Marum obtained permission to buy the latest, improved air-pump and a

double-cylinder pressure-pump from John Cuthbertson on 31 October, 1788, and

139 H 142

these he ordered on the following day (MV). The pressure-pump with a mounted

receiver arrived on 8 May, 1789, with a bill: “Voor een nieuwe geinventeerde dub-

belde pers-pump [sic] met een gemonteerde cylinder j 421” . Van Marum noted in

his journal that the cost of the pump alone was ƒ 280, while the receiver cost f 141

(MV). The best double air-pump, costing ƒ 330, arrived in November 1789, did not

find favour, was replaced by the pump made by Watt (Cat. 137)7'and Is now lost.

Also in November, Cuthbertson supplied a complete apparatus for the air and pressure-

pumps at the price ofy^ 444-10-0. This most probably refers to the three receivers

described below, Cat. 140.

The Rijksmuseum at Leyden has several air-pumps, including five by John

Cuthbertson, two dated 1790 and one dated 1789. Chaldecott has described the air

and pressure-pump made by George Adams Snr in 1762 for King George III, as well

as a similar pump, in the same collection, to the design of John Smeaton, which was

made c. 1752. When new, Smeaton’s pump could achieve a vacuum of a little under

t .0 torr, whereas ordinary pumps could reduce the pressure to about 6.0 torr. When

used as a pressure-pump, Smeaton’s could produce about three atmospheres.

A variety of experiments were performed to show the effects of compressed air.

Small animals were put inside a pressure receiver, water jets could be produced, and

the Magdeburg hemispheres were shown when the external pressure was greater than

that inside them.

Whiston (,1714) Pneumaticks II, fig. 1, III, fig. 1, 2; ’s Gravesande (1725) book 2,

part III, chap. 16 on the pump, chap. 17, twenty-two experiments; Desaguliers

(1744) Lecture XI; ’s Gravesande (1748) LXIV, LXV showing an improved pump;

Cuthbertson (1787); Crommclin (1951) 32—34, 55—57 > Chaldecott (1951) 31 f, no. 100,

Smeaton’s pump; no. 101, Adams’ pump.

Inv. 22jl