stance, considering its importance, and a reproach to those chemists

who have had it in their power to ascertain its nature.

Calcareous spar crystallized in dodecahedrons sometimes also occurs

in this vein. So I am told does sulphate o f barytes; but I was not

so lucky as to observe any specimens of that rare mineral in Sweden,

though so abundant in Great Britain. Specimens o f mountain cork

likewise occur occasionally. I saw several preserved in a small mineral

cabinet belonging to the mine. There is also a mineral occasionally

met with, (though I did not see it,) which is considered in Sweden as

the Aplome o f Haiiy. Its colour is brown, and it occurs crystallized

in irregular dodecahedrons with trapezoidal sides. It has but little

lustre, and its specific gravity is 3 -902. According to the analysis o f

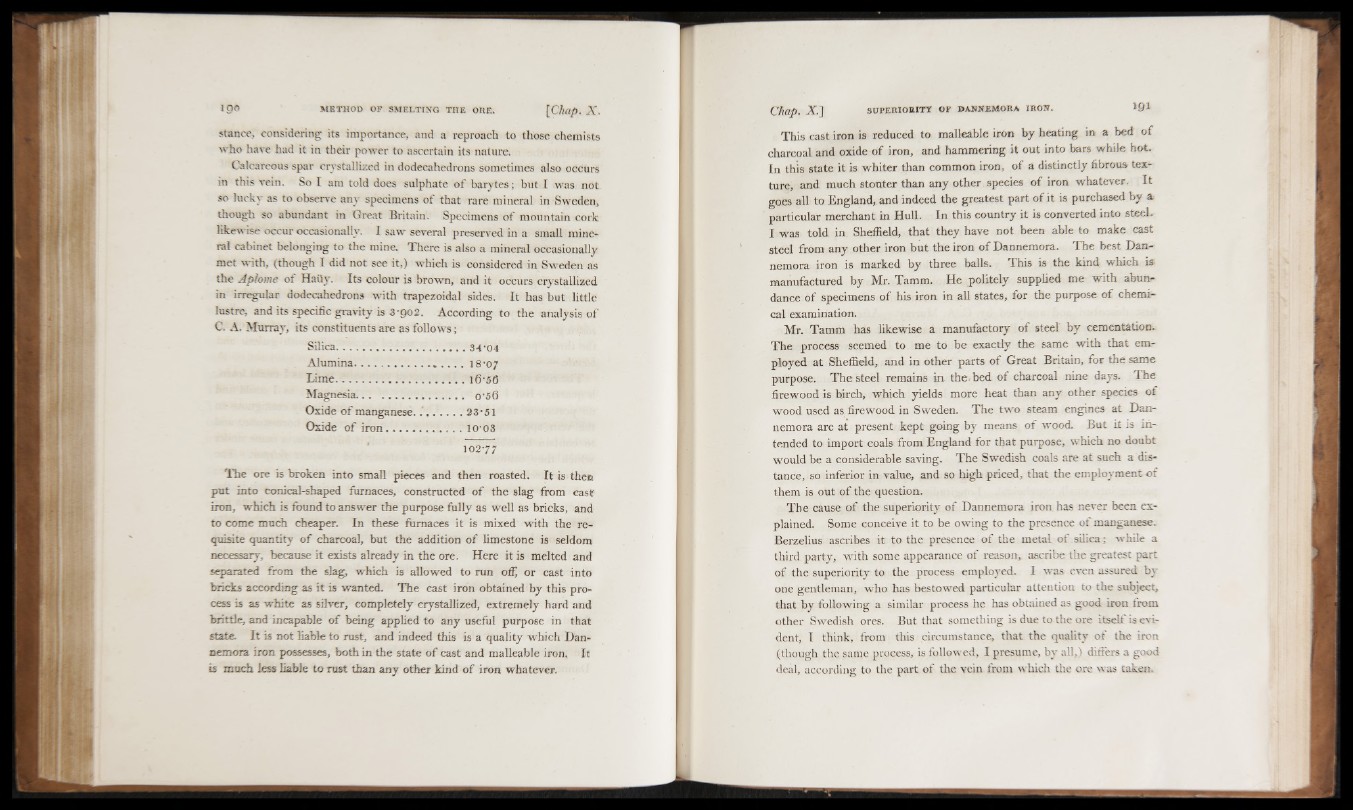

C. A. Murray, its constituents are as follows;

Silica..........................................34*04

Alumina....................................18*07

Lime. : . . . . 1 ........................... i6*sG

Magnesia.................................. 0*06

Oxide o f manganese. ........... 23*51

Oxide o f iron .................... 10*03

102*77

The ore is broken into small pieces and then roasted. It is then

put into conical-shaped furnaces, constructed o f the slag from cast

iron, which is found to answer the purpose fully as well as bricks, and

to come much cheaper. In these furnaces it is mixed with the requisite

quantity o f charcoal, but the addition o f limestone is seldom

necessary, because it exists already in the ore. Here it is melted and

separated from the slag, which is allowed to run off or cast into

bricks according as it is wanted. The cast iron obtained by this process

is as white as silver, completely crystallized, extremely hard and

brittle, and incapable of being applied to any useful purpose in that

state. It is not liable to rust, and indeed this is a quality which Dan-

nemora iron possesses, both in the state o f cast and malleable iron. I t

is much less liable to rust than any other kind o f iron whatever.

This cast iron is reduced to malleable iron by heating in a bed o f

charcoal and oxide of iron, and hammering it out into bars while hot.

In this state it is whiter than common iron, o f a distinctly fibrous texture,

and much stouter than any other species of iron whatever. It

goes all to England, and indeed the greatest part of it is purchased by a

particular merchant in Hull. In this country it is converted into steel.

I was told in Sheffield, that they have not been able to make cast

steel from any other iron but the iron of Dannemora. The best Dan-

nemora iron is marked by three balls. This is the kind which is

manufactured by Mr. Tamm. He politely supplied me with abundance

of specimens o f his iron in all states, for the purpose o f chemical

examination.

Mr. Tamm has likewise a manufactory o f steel by cementation.

The process seemed to me to be exactly the same with that employed

at Sheffield, and in other parts of Great Britain, for the same

purpose. The steel remains in the. bed of charcoal nine days. The

firewood is birch, which yields more heat than any other species of

wood used as firewood in Sweden. The two steam engines at Dannemora

are at present kept going by means o f wood. But if is intended

to import coals from England for that purpose, which no doubt

would be a considerable saving. The Swedish coals are at such a distance,

so inferior in value, and so high priced, that the employment of

them is out of the question.

The cause o f the superiority o f Dannemora iron has never been explained.

Some conceive it to be owing to the presence o f manganese.

Berzelius ascribes it to the presence of the metal of silica; while a

third party, with some appearance of reason, ascribe the greatest part

of the superiority to the process employed. I was even assured by

one gentleman, who has bestowed particular attention to the subject,

that by following a similar process he has obtained as good iron from

other Swedish ores. But that something is due to the ore itself is evident,

I think, from this circumstance, that the quality o f the iron

(though the same process, is followed, I presume, by all,) differs a good

deal, according to the part o f the vein from which the ore was taken.